welded wire mesh is a vital component in modern construction. This durable material consists of a series of vertical and horizontal wires welded together at intersections. Its robust structure enhances strength and stability in various applications. According to industry expert John Smith, "Welded wire mesh is essential for reinforcing concrete, ensuring long-lasting durability."

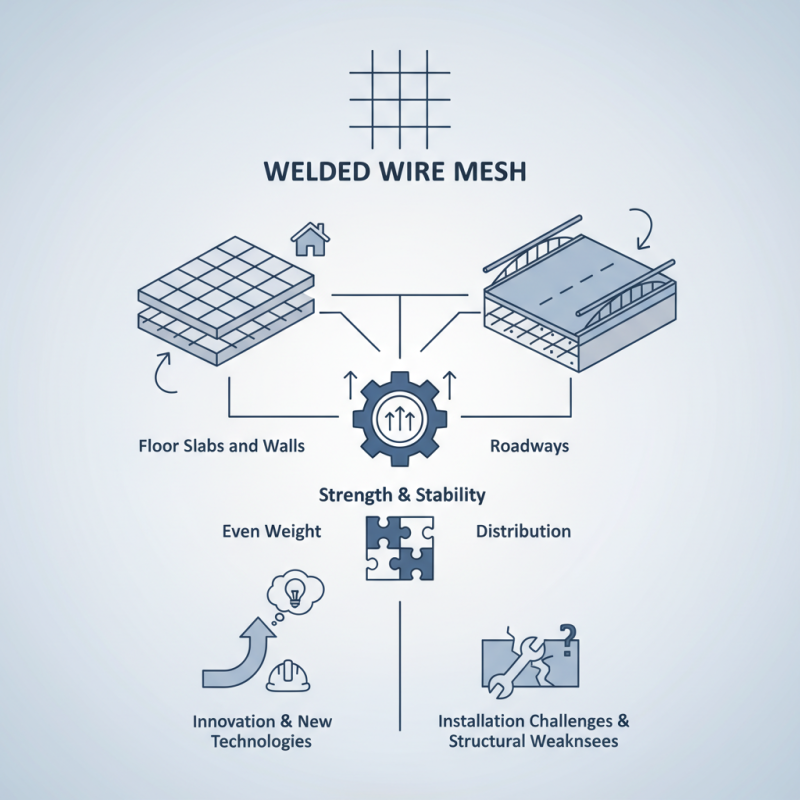

In construction, welded wire mesh serves multiple purposes. It is commonly used in floor slabs, walls, and even roadways. This versatile material provides excellent support, distributing weight evenly. Despite its many benefits, some challenges exist. Installation may require careful planning and skilled labor. Flaws in placement can lead to structural weaknesses.

As the construction industry evolves, so does the use of welded wire mesh. New technologies improve its strength and applications. However, constant innovation raises questions about adequacy and effectiveness. Experts stress the importance of staying informed and adapting practices to ensure safety and efficiency.

Welded wire mesh is a vital component in construction. It consists of intersecting steel wires welded together at specific intervals. This creates a grid-like structure that is both strong and reliable. The composition typically includes high-strength steel, which enhances its durability. The mesh is often coated with zinc to resist corrosion, extending its lifespan.

In construction, welded wire mesh is employed in various applications. It is widely used in concrete reinforcement. Workers place the mesh within concrete slabs to enhance strength and stability. This helps prevent cracking. The mesh provides a framework that distributes loads evenly. Additionally, it is used in fencing and as a support for plaster or masonry. However, improper installation can lead to structural issues. Therefore, attention to detail is crucial when using welded wire mesh. Understanding its properties can guide better applications in different construction projects.

Welded wire mesh is widely used in construction. It consists of thin wires welded together at intersections. This mesh provides strength and stability. Different types serve various purposes.

One common type is standard welded wire mesh. It is often used for concrete reinforcement. The mesh helps distribute loads evenly. Another type is heavy-duty welded wire mesh. This is suitable for demanding applications, like industrial flooring. The larger diameter wires offer superior strength.

In some projects, custom welded wire mesh is essential. Builders may require unique sizes and shapes. It can be a challenge to specify the exact needs. However, getting this right is critical for the integrity of the structure. Overall, choosing the right type of welded wire mesh is vital.

Welded wire mesh is a versatile material commonly used in construction. It consists of steel wires welded together in a grid pattern. This design enhances strength and durability. It is often used in structural elements like slabs, walls, and foundations.

One of the main applications of welded wire mesh is in concrete reinforcement. It adds tensile strength to concrete structures, preventing cracks. When embedded in concrete, it provides stability and supports heavy loads. It's essential to ensure proper spacing between the wires for an effective outcome.

Tips: Always check the mesh specifications before installation. A wrong choice can lead to structural issues. Make sure to use the right gauge to ensure strength.

Another area for welded wire mesh is in precast concrete products. It's integrated into components like beams and panels, enhancing their load-bearing capacity. However, sometimes the mesh may not be adequately placed, leading to uneven strength distribution. It's crucial to plan the layout carefully.

Tips: Regular inspections can help identify problems early. Don't hesitate to seek professional advice if unsure about installation practices. Proper guidance can prevent costly mistakes.

Welded wire mesh is increasingly popular in building projects. Its advantages make it a preferred choice for many construction applications. According to a report by Grand View Research, the global welded wire mesh market is expected to grow significantly, reaching a value of over $6 billion by 2025. This trend emphasizes its rising importance in construction.

One major advantage of using welded wire mesh is its strength and durability. It is resistant to corrosion and can withstand various environmental conditions. This makes it suitable for different structures, including foundations and walls. A recent study noted a significant reduction in construction costs when welded wire mesh was used compared to traditional methods. However, some construction teams still hesitate to adopt this material fully, often due to the perceived complexity of installation.

Another benefit is its versatility. Welded wire mesh can be adapted for various applications, from concrete reinforcement to animal enclosures. It enhances structural integrity while allowing for faster assembly. However, some projects may face challenges, such as ensuring the mesh fits perfectly within design plans. These imperfections can lead to delays and increased costs. Proper planning and execution are crucial to maximize the benefits of this material.

Welded wire mesh is widely used in construction for reinforcement. Its installation requires specific techniques to ensure effectiveness. Proper alignment is essential. Mesh should be laid out straight, avoiding any twist or bend. Gaps between the mesh sheets can weaken the structure. According to a report by the International Wire and Mesh Association, proper installation can enhance load-bearing properties by up to 30%.

Before installation, site preparation is crucial. The area must be cleared of debris and compacted. Uneven surfaces can lead to instability in the mesh. Workers should check for imperfections. Poorly manufactured mesh can cause issues down the line. Sometimes, even small mistakes can lead to major structural failures.

Secure connections are vital during the installation. Each intersection must be tightly welded or tied. Loose connections can compromise the integrity of the framework. Additionally, using the right tools increases efficiency. A survey from the Construction Industry Institute highlighted that 15% of rework comes from installation errors with welded wire. Addressing these issues is important for long-term durability.

| Dimension Type | Specification | Common Uses | Installation Techniques |

|---|---|---|---|

| 2"x2" Mesh | 12 Gauge | Reinforcing concrete | Laying flat before pouring concrete |

| 4"x4" Mesh | 10 Gauge | Paving sidewalks | Overlapping joints and securing with ties |

| 6"x6" Mesh | 8 Gauge | Wall reinforcement | Cutting to size and welding on-site |

| 8"x8" Mesh | 6 Gauge | Animal enclosures | Attaching to posts with nails or ties |