In the ever-evolving landscape of industrial machinery, understanding the various hydraulic cylinder types is crucial for optimizing performance and efficiency. These cylinders play an essential role in numerous applications, ranging from construction and manufacturing to aerospace and automotive industries. As technology advances, the design and functionality of hydraulic cylinders continue to innovate, leading to improved capabilities and versatility. This ultimate guide aims to demystify the different hydraulic cylinder types, exploring their unique features, advantages, and specific applications. By gaining insight into these components, professionals can make informed decisions when selecting the appropriate hydraulic cylinder for their projects, driving productivity and paving the way for a more efficient future in hydraulic systems.

Join us as we delve into this essential topic that lays the groundwork for understanding the pivotal role of hydraulic cylinders in modern engineering.

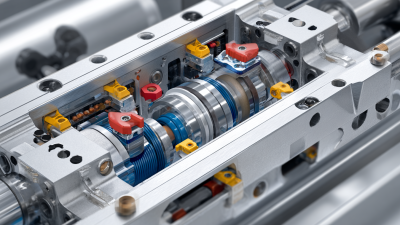

Hydraulic cylinders are critical components in various industries, serving as mechanical actuators that convert hydraulic energy into linear motion. Defined simply, a hydraulic cylinder consists of a cylinder barrel, a piston, and hydraulic fluid, which work together to generate force. In 2021, the global hydraulic cylinder market was valued at approximately USD 14.3 billion and is expected to grow to USD 18.3 billion by 2027. This growth indicates the increasing reliance on hydraulic systems in sectors such as construction, manufacturing, and maritime applications.

For professionals navigating the hydraulic industry, understanding the specific types of hydraulic cylinders—such as single-acting and double-acting cylinders—can significantly impact operational efficiency. A double-acting cylinder allows movement in both directions, making it ideal for applications that require more controlled manipulation. **Tip:** When selecting a hydraulic cylinder, consider the load requirements and the operating environment to choose the right type efficiently.

Additionally, advanced technologies like hydraulic power take-off (PTO) units are now being integrated into systems, such as wave energy converters, to optimize energy transformation processes. Keeping abreast of such innovations can lead to better implementation strategies in hydraulic applications. **Tip:** Regularly review industry reports and case studies to stay updated on trends and technologies that could enhance your operations.

| Hydraulic Cylinder Type | Definition | Functionality | Common Applications |

|---|---|---|---|

| Single-Acting Cylinder | A cylinder that exerts force in one direction while retracting through a spring or external force. | Used for pushing applications with return assistance. | Forklifts, material handling, and compacting. |

| Double-Acting Cylinder | A cylinder that can exert force in both extension and retraction by using hydraulic fluid. | Provides power for both movements, allowing for more versatility in operations. | Excavators, presses, and automation machinery. |

| Telescopic Cylinder | A cylinder that consists of multiple nested sections allowing for extended length without a proportional increase in retracted length. | Ideal for applications requiring a long stroke with minimal retraction space. | Dump trucks, aerial lifts, and construction equipment. |

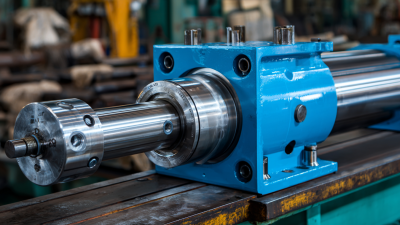

| Tie Rod Cylinder | Consists of a cylinder barrel, piston, and tie rods to secure the end caps, ensuring durability under high pressure. | More robust than welded cylinders and suited for high-pressure applications. | Manufacturing machinery, agricultural equipment, and heavy lifting. |

| Welded Cylinder | A compact cylinder designed for high-pressure applications, constructed from a single piece of steel for strength. | Minimizes the risk of leakage and enhances reliability in harsh environments. | Mobile equipment, mining, and offshore machinery. |

When it comes to hydraulic cylinders, understanding the various types and their specific applications is crucial for optimizing performance in any hydraulic system. Common types include double-acting, single-acting, and telescopic cylinders. Double-acting cylinders can exert force in both directions, making them ideal for applications requiring back-and-forth movement, such as in construction equipment. Single-acting cylinders, on the other hand, only apply force in one direction and rely on a spring return, which is useful in situations where a load can return to its original position without assistance.

Tip: When selecting a hydraulic cylinder, consider the weight of the load and the space you have available. A telescopic cylinder, which extends and retracts in stages, can be a perfect solution for limited space applications where height or length restrictions exist.

Another important distinction is the distinction between standard and special-purpose cylinders. Standard cylinders are suitable for most applications, while special-purpose cylinders can be designed for extreme conditions or specific tasks, like those found in aerospace or heavy industrial applications. Understanding these distinctions allows engineers to select the appropriate cylinder for their specific operational needs.

Tip: Always account for the operating environment—consider factors such as temperature, humidity, and exposure to corrosive elements—when choosing hydraulic cylinders to ensure longevity and reliability.

Hydraulic cylinders play a crucial role across various industries, demonstrating their versatility and efficiency in applications ranging from construction to manufacturing. According to recent market reports, the global hydraulic cylinders market was valued at approximately $14.07 billion in 2020 and is projected to reach around $21.24 billion by 2030, with a compound annual growth rate (CAGR) of 4%. This growth underscores the increasing demand for hydraulic solutions that enhance operational productivity and reliability.

In construction, hydraulic cylinders are essential for operating heavy machinery, such as excavators and cranes, facilitating the lifting and moving of substantial loads. The advancements in hydraulic cylinder technology, including the introduction of alternatives to traditional tie-rod cylinders, contribute significantly to this sector. Notably, innovations are continuously evolving, with expectations for the hydraulic actuator market to reach $2.4 billion by 2022, driven by applications that require precision and robust performance. The integration of these hydraulic solutions across industries illustrates their importance in powering equipment and machinery effectively, ensuring seamless operations and superior output.

When selecting a hydraulic cylinder, several key factors must be carefully considered to ensure optimal performance and compatibility with your specific application. First and foremost, it is crucial to evaluate the working environment in which the hydraulic cylinder will operate. Parameters such as temperature, humidity, and exposure to harsh chemicals can significantly affect the choice of materials and seals. For instance, a cylinder operating in a corrosive environment may require coatings or materials that are resistant to these adverse conditions.

Another important factor is the required force and stroke length for your application. Accurate calculations based on load requirements will help determine the appropriate cylinder size and type. This includes considering the pressure rating and the type of actuation (single-acting or double-acting). Additionally, the mounting style and orientation—such as front or rear mounting—must align with your machinery’s design to facilitate efficient operation. Balancing these considerations will help you choose the most suitable hydraulic cylinder type, ensuring it meets the operational demands and enhances overall system performance.

Maintaining hydraulic cylinders is crucial for ensuring their optimal performance and longevity. One of the top tips for maintenance is to regularly check for any leaks. Small leaks can lead to significant issues if not addressed promptly. Inspect the cylinder seals and connections periodically to ensure there’s no oil seeping out, which could indicate wear and tear. Promptly replacing worn seals will help maintain the efficiency of the hydraulic system.

Another important aspect of maintenance is proper lubrication. Hydraulic cylinders function best when their moving parts are adequately lubricated. Be sure to follow the manufacturer's guidelines regarding lubrication intervals and the type of grease to use. Over-lubrication can be just as harmful as under-lubrication, leading to blockage or increased wear. Additionally, it’s beneficial to keep the working environment clean and free of debris that can cause abrasion or contamination.

Lastly, keep an eye on the operating temperature of the hydraulic cylinder. Excessive heat can degrade the hydraulic fluid and lead to premature failure. If the temperature exceeds the recommended limits, consider evaluating the cooling system and addressing potential issues that may be causing overheating. Regular temperature monitoring can help prevent catastrophic failures and ensure the cylinder operates effectively.