In modern manufacturing, a Metallurgical Bridge Crane plays a crucial role. This equipment is designed to transport heavy materials with remarkable precision. Dr. Jonathan Steele, a leading expert in industrial machinery, once stated, “A Metallurgical Bridge Crane transforms the workflow in steel plants.” His observation aligns with the realities of heavy material handling.

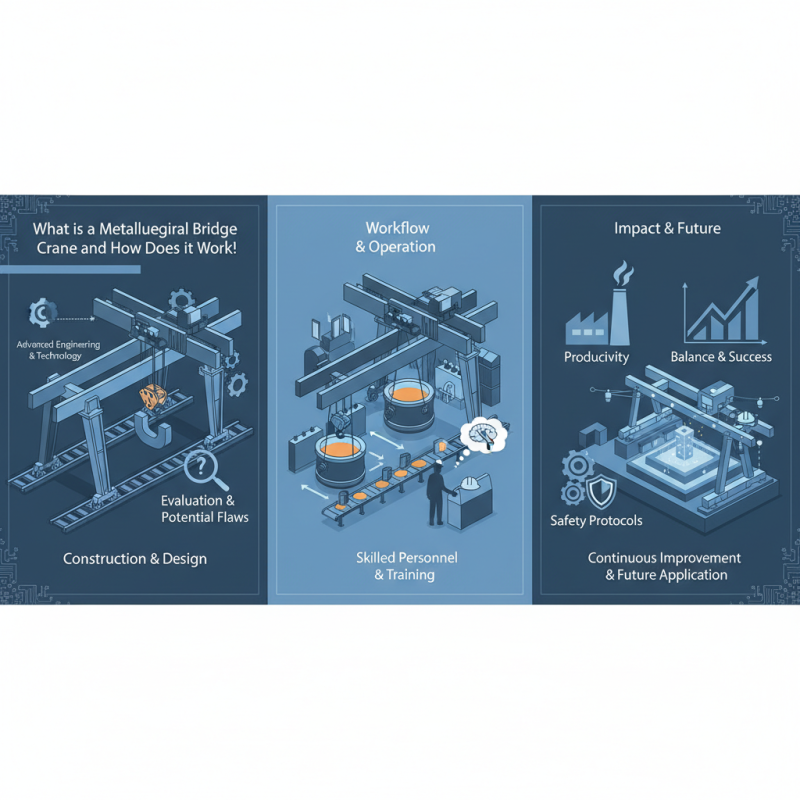

The construction of a Metallurgical Bridge Crane integrates advanced engineering and technology. This crane operates with overhead tracks, allowing it to maneuver efficiently in challenging environments. However, the design requires continuous evaluation. There can be flaws that hinder its full potential. Understanding these weaknesses is vital for improvement.

Moreover, the operation of a Metallurgical Bridge Crane demands skilled personnel. Mismanagement or lack of training can lead to accidents. Ensuring that workers are well-trained remains a constant challenge. The industry must strive to enhance safety protocols while maintaining productivity. This balance is essential for the successful application of Metallurgical Bridge Cranes.

A metallurgical bridge crane is a vital piece of equipment in metal processing industries. It is designed to handle heavy loads, such as molten metal and large steel products. This crane operates on a track system. It consists of a horizontal bridge that moves along two parallel tracks. The bridge is supported by vertical frames on each end.

These cranes are often used in foundries and steel mills. They can lift enormous weights, sometimes exceeding hundreds of tons. Operators must be highly trained. Safety is crucial when dealing with molten materials. The crane's design minimizes risks. However, even with advanced technology, human error remains a concern.

The controls for a metallurgical bridge crane can be complex. Operators need to understand the mechanics thoroughly. Miscommunication can lead to accidents. Regular maintenance checks are essential. These ensure the crane functions properly and safely. While it is an effective solution, there are always areas for improvement. Training programs must evolve. Emphasizing safety protocols is necessary for the industry's future.

This bar chart displays the load capacities of various metallurgical bridge cranes, showcasing their performance and capabilities in handling heavy loads.

A metallurgical bridge crane is a vital piece of equipment in the metalworking industry. It is specially designed to handle heavy loads, such as ingots and steel products. Key components of this crane include the bridge, hoist, trolley, and controls. Each plays a critical role in the crane’s operation and efficiency.

The bridge acts as the framework that supports the trolley and hoist. The trolley moves along the length of the bridge, allowing the hoist to lift and lower materials. According to industry reports, these cranes can handle loads exceeding 100 tons safely. Proper maintenance of each component is essential to prevent breakdowns.

**Tip:** Regular inspections can avoid costly downtimes.

The hoist mechanism is crucial for the lifting operation. It’s often equipped with different types of lifting hooks. Operators need to be well-trained to manage the loads effectively. Even experienced users can occasionally miscalculate load weights, leading to safety hazards.

**Tip:** Always verify load weights before lifting.

Controls for the crane can vary from simple pendant switches to advanced remote systems. Operators should familiarize themselves with the controls. Confusion can lead to serious safety risks or machinery damage. Emphasizing training and awareness will improve operational safety in the workplace.

| Component | Description | Function | Material |

|---|---|---|---|

| Bridge | The main framework that spans the workshop | Support for the load and movement | Steel |

| Hoist | Mechanism that lifts and lowers the load | Lifting heavy materials | High-strength alloy |

| Trolley | Moves along the bridge | Horizontal movement of the load | Steel |

| Control System | Electromechanical system for operation | Controls motion of the crane | Electrical components |

| End Truck | Supports the bridge and allows it to move | Stability and movement | Heavy-duty steel |

Metallurgical bridge cranes play a crucial role in heavy industries. Their operation revolves around strategic lifting and transporting of molten metal and heavy materials. These cranes utilize a horizontal bridge that moves along two parallel tracks. This design allows them to cover large areas within a facility, proving effective in steel mills and foundries.

The principle of operation involves several components working in unison. The overhead bridge supports a hoist, which can often rotate in multiple directions. This enables precise control when lifting and placing heavy loads. Operators usually control these cranes using remote controls or pendant stations. They need to be mindful of the load's weight and balance to ensure safety.

While the technology is impressive, it is not flawless. Operators may face challenges with equipment maintenance and load management. Human error can impact efficiency and safety. Regular training and inspections are essential to minimize these risks. Even advanced systems require constant attention and updates. Continuous improvement is key to maximizing performance in such demanding environments.

Metallurgical bridge cranes are crucial in the metallurgical industry. They excel in handling heavy materials like molten metal and alloys. According to a recent industry report, about 60% of such cranes are used in steel production. Their design allows for efficient movement across large areas. This reduces the risk of accidents during material transport.

These cranes operate on a rail system, offering stability and precision. They can lift loads that reach up to 100 tons. This capacity is significant, considering that improper lifting can lead to severe accidents. Additionally, most cranes are equipped with safety features, yet challenges remain. For instance, maintenance issues can lead to unexpected downtimes. The complexity of their mechanics means that regular inspections are necessary.

In the foundry sector, these cranes add significant value. A study highlighted that utilizing bridge cranes improves production efficiency by approximately 30%. Managers often need to balance speed with safety. Sometimes, operational decisions lead to overloading, creating risks. Continuous training and awareness could help mitigate such issues. The integration of innovative technologies remains a critical area for improvement.

Maintenance is crucial for bridge cranes. Regular inspections help identify wear and tear. Check the cables and hoists monthly. Inspect the crane’s wheels and tracks for damage. Over time, these components can falter, leading to accidents. Operators must stay vigilant about noise changes or unusual vibrations. Unattended issues can escalate quickly.

Safety is paramount when operating these cranes. Operators should wear appropriate gear. Training programs must be comprehensive and ongoing. Conduct drills regularly to prepare for emergencies. Always have a functional emergency stop button within reach. Ensure the workspace remains clear of obstacles. This avoids collisions during operation.

Even with established protocols, mistakes can happen. Human error is a significant factor in crane operations. Encourage open communication among team members. Feedback loops can help improve safety measures. Reflecting on past incidents offers valuable lessons. Analyzing missteps fosters a safer environment.