In today’s rapidly evolving industrial landscape, the demand for enhanced efficiency in Hydraulic Cylinder Design is more crucial than ever. According to a recent report by MarketsandMarkets, the global hydraulic cylinder market is projected to reach $12.8 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.6% from 2020. This growth is driven by the increasing need for advanced automation and the adoption of innovative technologies across sectors such as construction, agriculture, and manufacturing. As industries strive for operational excellence, optimizing the design of hydraulic cylinders is paramount to achieving higher performance and reliability. This guide will explore various innovative solutions that can refine hydraulic cylinder design, thereby enhancing efficiency and extending service life while meeting the rigorous demands of modern applications.

When optimizing hydraulic cylinder design, establishing key performance metrics is crucial for enhancing efficiency and functionality. These metrics serve as benchmarks to evaluate the performance of hydraulic systems and ensure they meet industry standards. Critical factors to consider include load capacity, cycle time, and energy efficiency. By measuring these parameters, designers can identify areas for improvement and implement innovative solutions that streamline production processes and reduce operational costs.

Additionally, integrating advanced simulation tools can further refine the design optimization process. By utilizing computational fluid dynamics (CFD) and finite element analysis (FEA), engineers can predict how a hydraulic cylinder will perform under various conditions. This predictive analysis enables the identification of potential failures before physical prototypes are built, saving time and resources. Ultimately, by focusing on defining and optimizing key performance metrics, the design of hydraulic cylinders can achieve new levels of effectiveness and reliability, paving the way for superior engineering solutions in various applications.

| Performance Metric | Description | Target Value | Current Value | Improvement Needed (%) |

|---|---|---|---|---|

| Cycle Time | Time to complete one full extension and retraction | 15 seconds | 20 seconds | 25% |

| Energy Efficiency | Energy consumed per cycle (kWh) | 0.5 kWh | 0.8 kWh | 60% |

| Load Capacity | Max load supported by the cylinder (tons) | 10 tons | 9 tons | 10% |

| Failure Rate | Number of failures per 1000 cycles | 2 | 4 | 100% |

| Cost Efficiency | Cost per cycle operation ($) | $0.10 | $0.15 | 50% |

When it comes to enhancing hydraulic cylinder efficiency, the choice of materials and coatings plays a crucial role. Opting for advanced alloys and composites can significantly improve the performance and lifespan of hydraulic cylinders. For instance, materials such as high-strength steels and lightweight aluminum alloys are gaining popularity for their superior strength-to-weight ratio and resistance to corrosion. These materials not only enhance durability but also contribute to weight savings, which is essential for improving the overall efficiency of hydraulic systems.

When it comes to enhancing hydraulic cylinder efficiency, the choice of materials and coatings plays a crucial role. Opting for advanced alloys and composites can significantly improve the performance and lifespan of hydraulic cylinders. For instance, materials such as high-strength steels and lightweight aluminum alloys are gaining popularity for their superior strength-to-weight ratio and resistance to corrosion. These materials not only enhance durability but also contribute to weight savings, which is essential for improving the overall efficiency of hydraulic systems.

Furthermore, the application of specialized coatings can provide additional benefits. For example, utilizing ceramic coatings can minimize friction and wear, leading to smoother operation and reduced energy consumption. Similarly, applying self-lubricating composite coatings can prevent the build-up of wear debris, thus enhancing the reliability and maintenance intervals of hydraulic cylinders. By integrating these innovative materials and cutting-edge coatings into the design process, engineers can achieve optimal performance while addressing challenges such as environmental impact and operational costs in hydraulic systems.

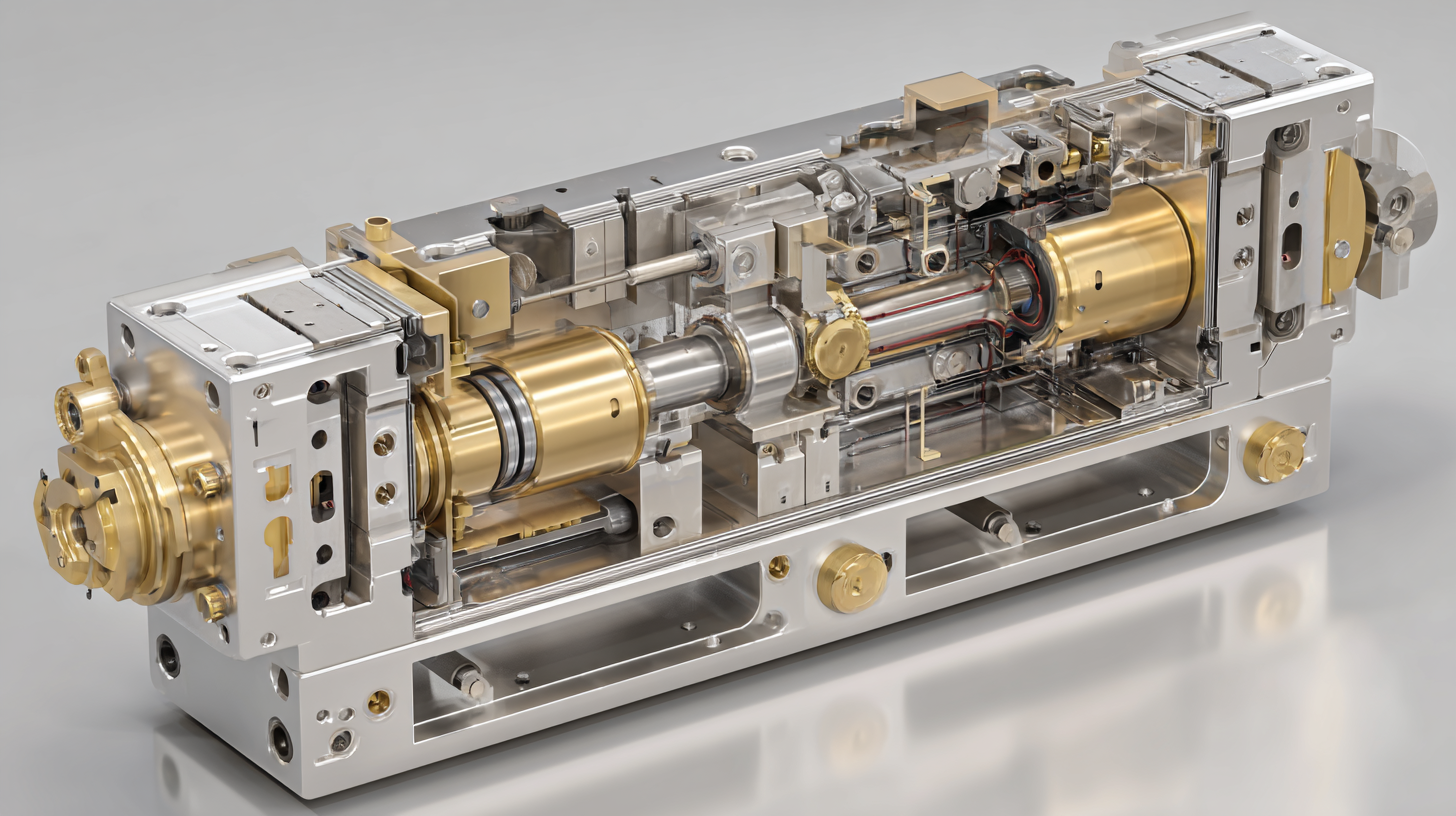

In the realm of hydraulic cylinder design, the integration of advanced simulation tools has revolutionized the efficiency and accuracy of the development process. These tools allow engineers to create detailed virtual models that can simulate real-world conditions and behaviors, facilitating a deeper understanding of how different variables affect performance. By analyzing these simulations, designers can quickly identify potential issues, optimize geometries, and enhance material selection, ultimately leading to more robust and reliable hydraulic systems.

Moreover, the use of advanced computational fluid dynamics (CFD) and finite element analysis (FEA) software enables unprecedented insights into flow dynamics and structural integrity. These simulations not only save time during the prototyping phase but also significantly reduce costs associated with materials and production. As a result, hydraulic cylinder designs can be fine-tuned with precision, leading to improved efficiency, reduced energy consumption, and longer service life. Embracing these innovative simulation techniques is essential for engineers aiming to push the boundaries of hydraulic technology while meeting the increasing demands of efficiency and sustainability.

This chart illustrates the efficiency improvements in hydraulic cylinder design over the past five years by utilizing advanced simulation tools. The data reflects the percentage of efficiency gains year over year, showcasing a significant trend toward optimized designs.

When designing hydraulic cylinders, prioritizing ergonomic and user-friendly features can significantly enhance both efficiency and user experience. An effective checklist can guide engineers and designers in creating hydraulic cylinders that not only perform well but also cater to the needs of operators. Key features to consider include adjustable handles, lightweight materials, and intuitive control systems, all of which contribute to minimizing operator fatigue and maximizing productivity.

Moreover, incorporating safety features is essential for user-friendly designs. This includes clear markings for operation and maintenance tasks, as well as built-in safety mechanisms that prevent mishaps during use. By ensuring these ergonomic principles are embedded in the design, manufacturers can create hydraulic cylinders that stand out in the market, similar to the latest reliable log splitters that offer a powerful performance without compromising on ease of use. Attention to these details not only enhances the overall functionality of hydraulic cylinders but also improves operator satisfaction and safety in various applications.

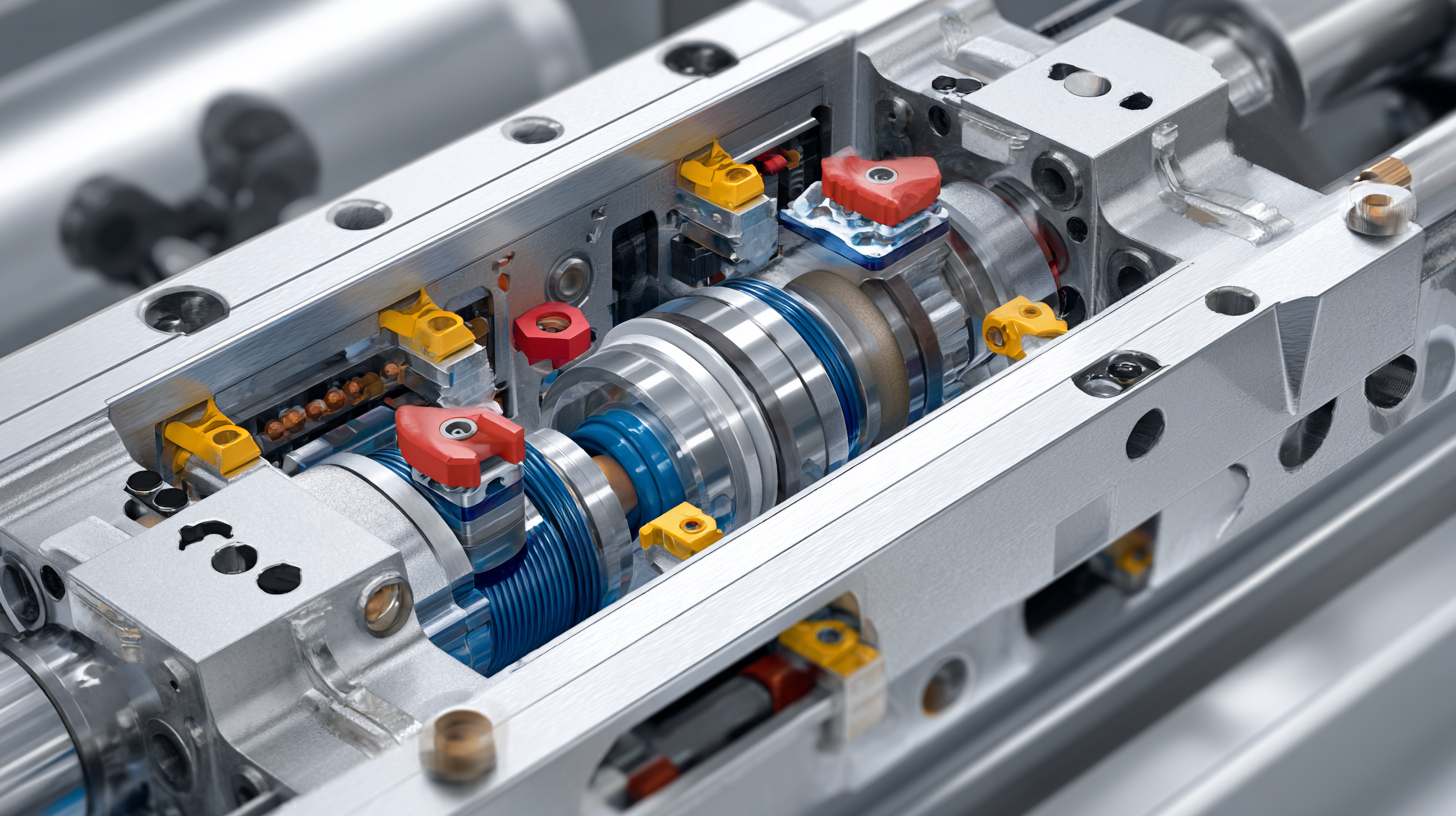

The performance of hydraulic cylinders is significantly influenced by the manufacturing processes employed during their production. Various methods, such as machining, welding, and surface treatment, determine not only the physical properties of the materials used but also their longevity and reliability in demanding applications. For instance, precision machining techniques can enhance the dimensional accuracy of the cylinder components, reducing leakage and improving overall efficiency. On the other hand, the choice of welding processes can impact the integrity of the materials, affecting their ability to withstand high pressures and extreme conditions.

Additionally, post-manufacturing processes like surface treatments play a crucial role in optimizing cylinder performance. Treatments such as hardening, coating, and polishing help improve wear resistance and corrosion protection, which are vital for the longevity of hydraulic cylinders operating in harsh environments. Investing in advanced manufacturing technologies can lead to the creation of more robust and efficient hydraulic systems, ensuring they meet the increasing demands of various industrial applications. Thus, a close examination of manufacturing processes is essential for achieving superior hydraulic cylinder design efficiency.