Selecting the best cylinder type for your application can add value by ensuring it is designed to address the unique functional and environmental requirements of your application. From ease of assembly and maintenance to ensuring the realization of expected service life, the right cylinder type, build style, mounting configuration, and other key design considerations can make a big difference.

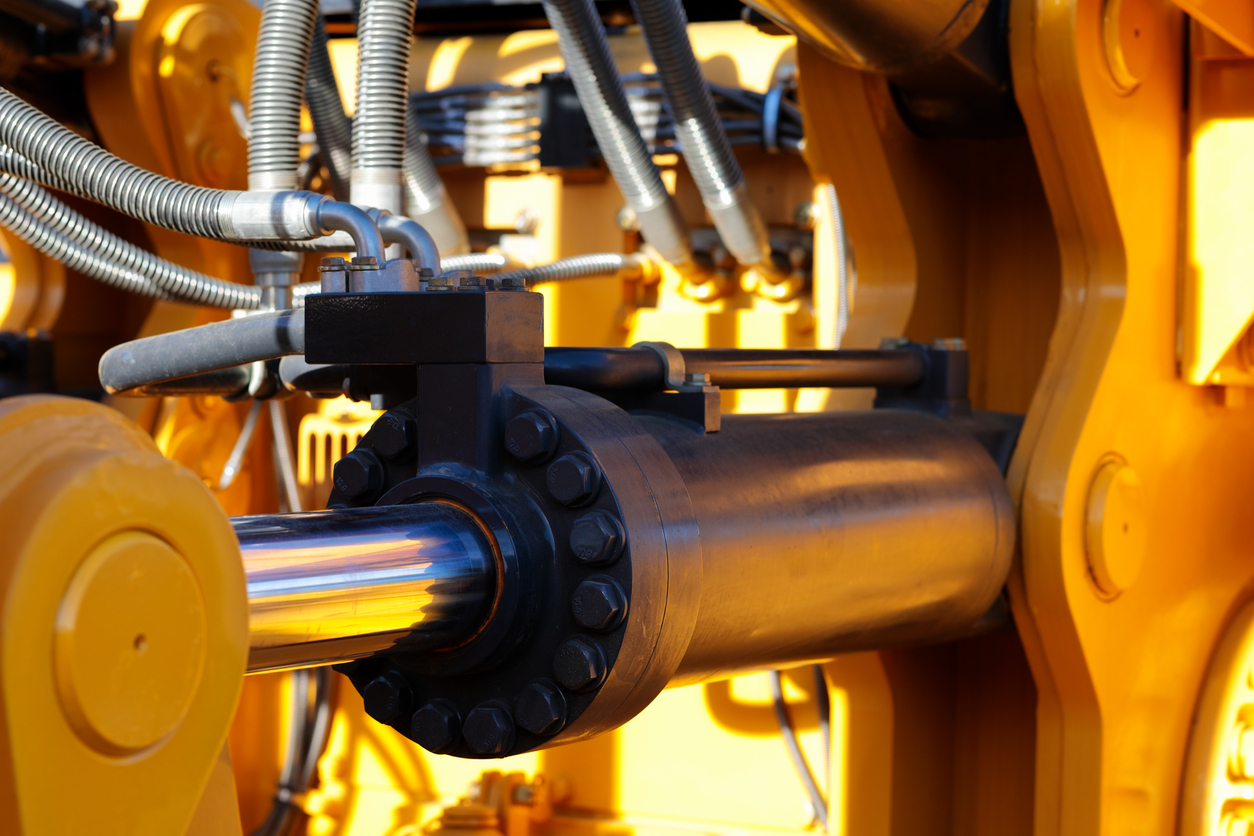

Hydraulic Cylinder Design Considerations

Hydraulic cylinder selection should take into consideration the functions required, the environment in which the cylinder will operate, cycle speed and frequency, operating parameters including system operating pressure, loading conditions, and potential pressure spikes or amplification, as well as service life expectancy, and other factors. Contact Aurelius today to discuss hydraulic cylinder selection and cylinder design considerations.

Why Select a Custom Hydraulic Cylinder?

Off-the-shelf hydraulic cylinders may not adequately address all of the unique design considerations for your application. You may end up making compromise in design, functionality, or service life. Selecting a custom hydraulic cylinder will allow you to choose the cylinder type and apply the design factors that deliver functionality, features, and performance that add the most value to your application.

Bore

The bore is the diameter of the cylinder tube. This is used to help you determine the piston area, maximum operation pressure, and the force the cylinder can exert. At Aurelius, our team can work with bore sizes from one to ten inches in diameter with wall thicknesses determined by specific safety factors.

Rod Diameter

The rod diameter of your hydraulic cylinder will impact its force and speed. It can also reduce the effective piston area on the rod side of the cylinder. To reduce cylinder force on the pull, use a larger rod diameter. Conversely, to increase the force of your cylinder, use a smaller rod diameter. Our team works with rod diameters ranging from ⅜ inch to five inches with a variety of material types and plating options.

Stroke Length

The stroke length is how far the piston must travel within its tube from the closed to open position. This indicates the size and speed of your hydraulic cylinder. At Aurelius, our team can work with stroke lengths from 0 to 20 feet.

Operating Pressure

Each application and piece of equipment requires different operating pressures. If you’re curious about what operating pressure is right for you, our team is here to help. We work with operating pressures up to 5000 PSI.

Smart Cylinders

Smart cylinders consist of position sensors that give you valuable information about your system. These solutions are used to improve safety and automation.

Applications in Nearly All Industries Can Benefit From Selecting a Custom Hydraulic Cylinder

Custom solutions deliver value by developing designs that are tailored to the requirements and environmental factors, deliver automation, and improve safety in many industries including:

- Rail

- Forestry

- Construction

- Material Handling

- Agriculture

- Specialty Industrial Applications

Contact Aurelius Manufacturing for Help with Hydraulic Cylinder Selection

Aurelius Manufacturing has been a trusted manufacturer of custom hydraulic cylinders for over 40 years. We take a collaborative design approach to each project. This allows us to work closely with your team to find a solution that adds the most value to your application. Our team is dedicated to quality, responsiveness, and reliable lead times to ensure you are getting the most out of your partnership with us. Contact our team today to get started.