In recent years, the global hydraulic solutions market has witnessed a significant transformation, propelled by technological advancements and increasing demands for efficient machinery. According to a report by ResearchAndMarkets, the hydraulic cylinder market is projected to reach USD 36.8 billion by 2026, driven primarily by the rise in automation across various industries.

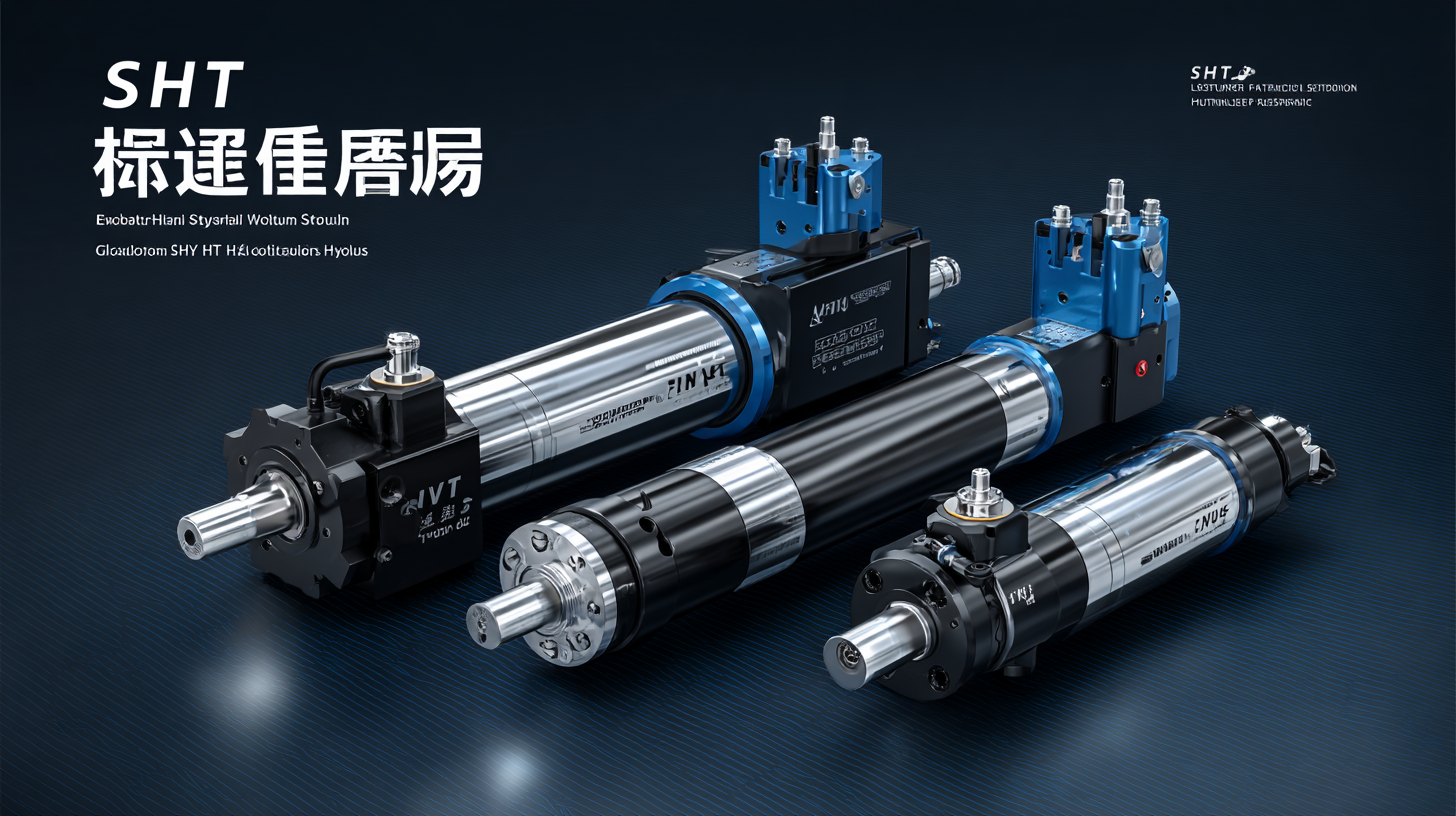

At the forefront of this evolution are Smart Hydraulic Cylinders, which integrate IoT technology and advanced sensors to enhance performance, monitoring, and efficiency. As industries seek to augment productivity and reduce operational costs, China's premium smart hydraulic cylinders have emerged as a testament to innovation, blending precision engineering with intelligent designs. This blog will explore how these cutting-edge solutions are shaping the future of hydraulic applications, positioning China as a leader in the global hydraulic sector.

The global hydraulic cylinder market is experiencing substantial growth, with projections estimating it to reach $21.5 billion by 2031, reflecting a 5.5% compound annual growth rate (CAGR). In this context, China's smart hydraulic cylinders are emerging as frontrunners, equipped with advanced features that cater to modern industrial demands. These cylinders are designed to enhance efficiency, reliability, and safety in various applications, making them an attractive choice for manufacturers seeking innovative solutions.

Key features of smart hydraulic cylinders in the Chinese market include integrated sensing technologies that offer real-time performance monitoring and predictive maintenance capabilities. This allows for timely interventions and reduces downtime, which is critical in high-stakes environments. Moreover, the adoption of smart hydraulic cylinders is complemented by their ability to improve energy efficiency and reduce operational costs, aligning with global sustainability goals. As industries evolve, these intelligent solutions are set to redefine the future of hydraulic systems, positioning China as a leader in this technological transformation.

The hydraulic solutions industry is experiencing a significant transformation driven by the adoption of advanced technology, particularly in smart hydraulic cylinders. According to a recent market analysis by Research And Markets, the global hydraulic cylinder market is projected to reach USD 25 billion by 2027, with a notable shift towards smart technologies. This growth highlights the increasing demand for enhanced efficiency, reliability, and safety in hydraulic systems across various sectors, including construction, manufacturing, and aerospace.

Smart hydraulic cylinders are engineered with advanced sensors and connectivity options that allow for real-time monitoring and diagnostics, leading to improved operational efficiency. A report from Allied Market Research indicates that incorporating smart technologies can reduce maintenance costs by up to 30% and significantly enhance performance. By leveraging data analytics, companies can proactively identify issues before they lead to equipment failure, thus minimizing downtime and optimizing productivity. As the industry moves towards smarter solutions, the benefits of such technology are becoming increasingly apparent, paving the way for a new era in hydraulic systems globally.

The smart hydraulic cylinder industry is experiencing transformative growth, driven by advancements in technology and rising demand from industries such as manufacturing and construction. According to a recent report by Grand View Research, the global hydraulic cylinder market is expected to reach $15.8 billion by 2025, with a significant portion attributed to smart hydraulic solutions. China's leading manufacturers are at the forefront of this revolution, bringing innovative designs and enhanced functionality to the market.

Top players like SANY, ZHENJIANG DONGFANG, and HAWE Hydraulik are spearheading this evolution, focusing on integrating IoT capabilities within hydraulic systems. These smart cylinders not only improve operational efficiency but also contribute to predictive maintenance, reducing downtime by up to 30%, as reported by market analysts at MarketsandMarkets. The emphasis on automation and remote monitoring in these hydraulic solutions is reshaping how industries operate, ensuring enhanced productivity and safety.

The competitive landscape is intensifying, with manufacturers investing in R&D to create more sophisticated products that meet the demands of a modern workforce. Industry estimates have shown that the adoption of smart hydraulics can improve energy efficiency by as much as 20%, showcasing the potential for significant cost savings. As China's hydraulic cylinder manufacturers continue to innovate, they are set to redefine standards in quality and performance on a global scale.

The advent of smart hydraulic technology is revolutionizing various application areas, from manufacturing to construction. Smart hydraulic cylinders, equipped with advanced sensors and control systems, enable real-time monitoring and precision control of hydraulic systems. This transformation leads to enhanced efficiency and reduced downtime in operations, as these cylinders can anticipate failures and signal maintenance needs before they lead to costly breakdowns. In environments where safety and reliability are paramount, such as in aerospace and automotive industries, the integration of smart technology ensures optimal performance under varying conditions.

Moreover, the integration of Internet of Things (IoT) capabilities in smart hydraulic systems fosters more intelligent automation. In sectors like agriculture, these systems facilitate precision farming by optimizing resource use and adapting to real-time data inputs. This not only boosts productivity but also promotes sustainable practices by minimizing waste. As industries increasingly adopt smart hydraulic solutions, the promise of efficiency, sustainability, and innovation is set to redefine operational standards, highlighting the pivotal role of China in spearheading these advancements in hydraulic technology.

| Application Area | Key Features | Benefits | Market Growth (%) |

|---|---|---|---|

| Automotive Industry | Advanced telemetry, real-time monitoring | Improved safety, efficiency enhancement | 6.5% |

| Construction Machinery | Load sensing, eco-friendly operation | Reduced operational costs, sustainability | 8.2% |

| Aerospace | High precision, lightweight materials | Enhanced performance, weight reduction | 10.1% |

| Marine Industry | Corrosion resistance, high durability | Longer lifecycle, higher reliability | 7.3% |

| Renewable Energy | Energy efficiency, smart grid integration | Sustainable solutions, cost-saving | 9.0% |

When utilizing hydraulic cylinders, safety and maintenance are paramount to ensure optimal performance and longevity. A well-maintained hydraulic cylinder can operate efficiently for up to 20,000 cycles before requiring significant repairs, according to a study by the International Hydraulic Engineering Association (IHEA). Regular inspection schedules should include checking for leaks, verifying the integrity of seals, and ensuring that all hydraulic fluid levels are adequate. Adhering to a strict maintenance schedule not only enhances safety but also minimizes downtime and operational costs.

Furthermore, operators should always keep a safety checklist that includes verifying the operational pressure against manufacturers' specifications and inspecting the mounting and connection points for signs of wear or damage. A report by the Hydraulic Manufacturers Association (HMA) indicates that improper maintenance practices account for approximately 30% of hydraulic system failures, emphasizing the need for comprehensive training for users. Implementing these practices can drastically reduce the risk of accidents while ensuring that hydraulic systems remain reliable and efficient, ultimately contributing to the success of industrial operations.