In the realm of advanced engineering solutions, the emergence of the Smart Hydraulic Cylinder has marked a significant innovation, particularly from leading manufacturers in China. Recent industry reports indicate a projected growth rate of over 6% annually in the hydraulic systems market, driven by increasing automation and demand for energy efficiency. Smart Hydraulic Cylinders, integrating IoT technology and advanced sensors, not only enhance functionality but also ensure optimal performance and real-time monitoring. These cylinders play a crucial role in various applications, including construction equipment, aerospace, and automotive industries, contributing to improved operational efficiency and reduced downtime. As global buyers seek reliable and cutting-edge hydraulic solutions, the excellence of Chinese manufacturers in producing Smart Hydraulic Cylinders becomes increasingly relevant, underscoring their importance in the international market landscape.

The rise of smart hydraulic cylinders in China's manufacturing sector marks a significant innovation, streamlining processes and enhancing efficiency in industries globally. Not only do these cylinders improve operational precision, but they also embody the kind of advanced technology that has made Chinese manufacturing a leader in the global market. Recent advancements illustrate how local companies are pioneering solutions that meet the rigorous demands of modern engineering applications, setting new standards for quality and performance.

Tip: When considering smart hydraulic cylinders for your projects, pay attention to features such as sensor integration and monitoring capabilities. These can drastically improve operational maintenance and reduce downtime.

Moreover, the introduction of the world's first 5000-ton class heavy-duty marine hydraulic cylinder in Jiangsu highlights China's commitment to breaking through technological barriers and reducing reliance on foreign products. This achievement not only emphasizes innovative designs but also showcases China's capability to produce high-quality machinery that meets global standards.

Tip: Engaging with manufacturers who prioritize research and development can ensure that you benefit from the latest innovations in hydraulic technology. Always look for collaborations that focus on sustainable and efficient production practices.

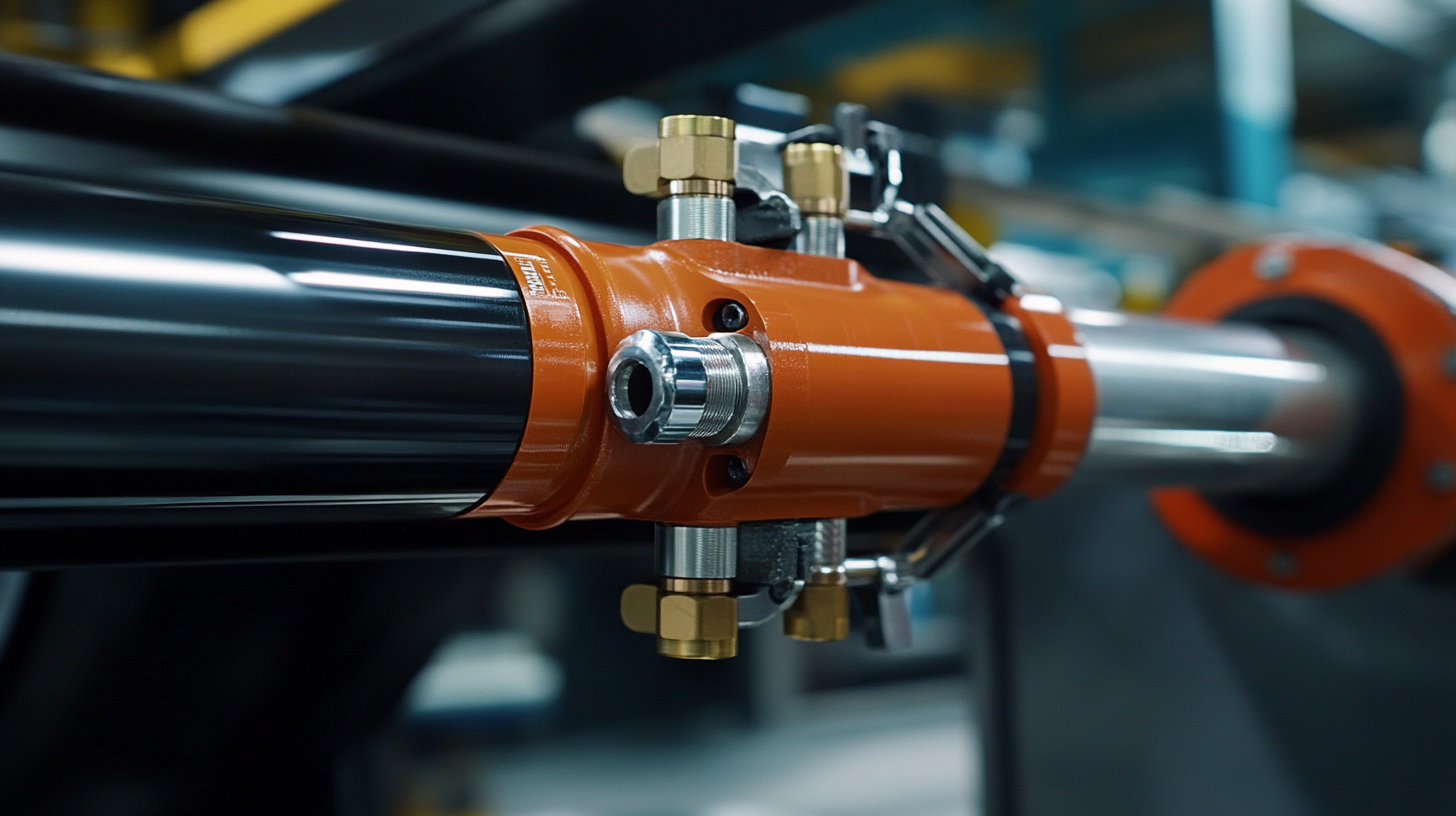

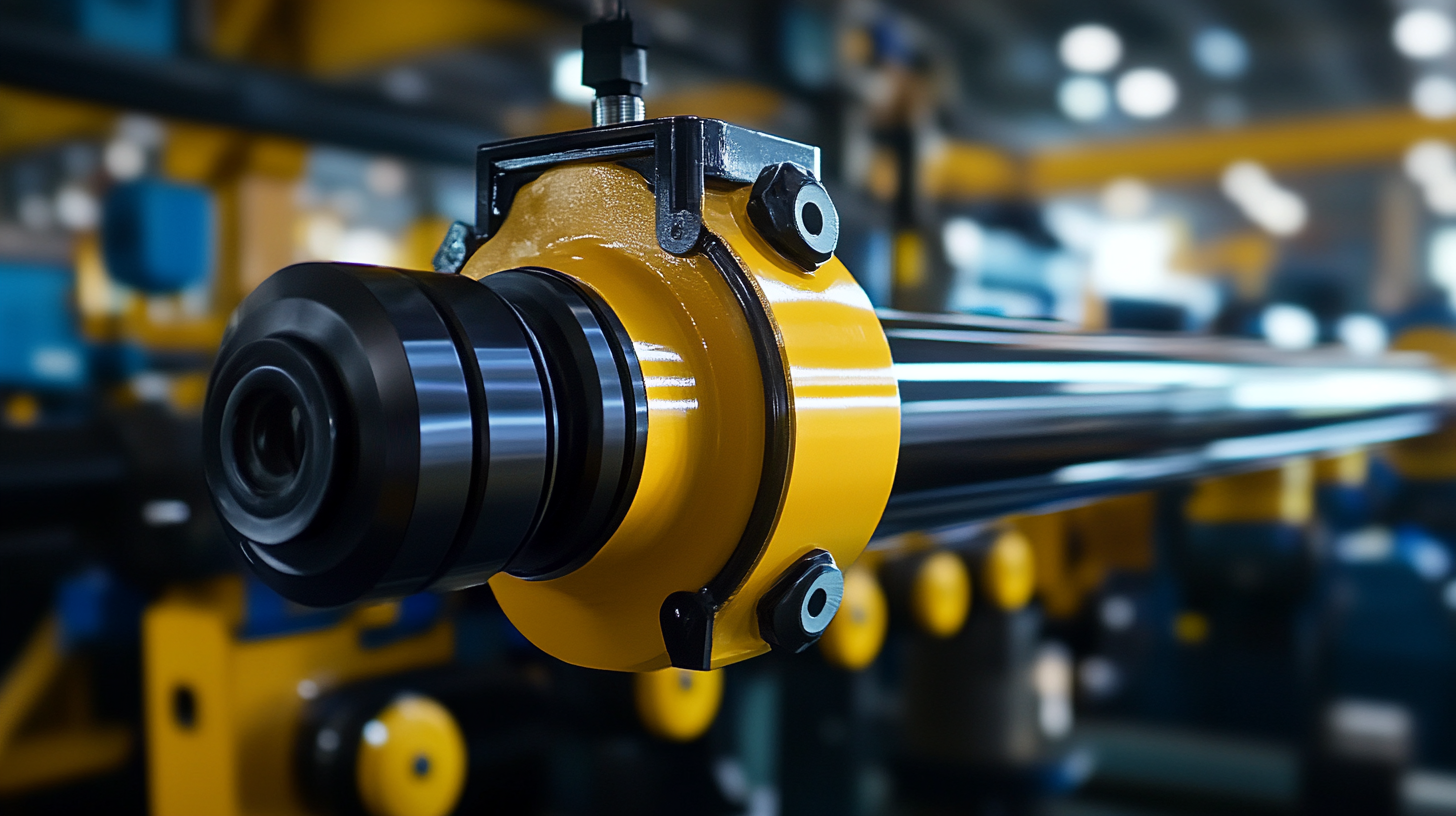

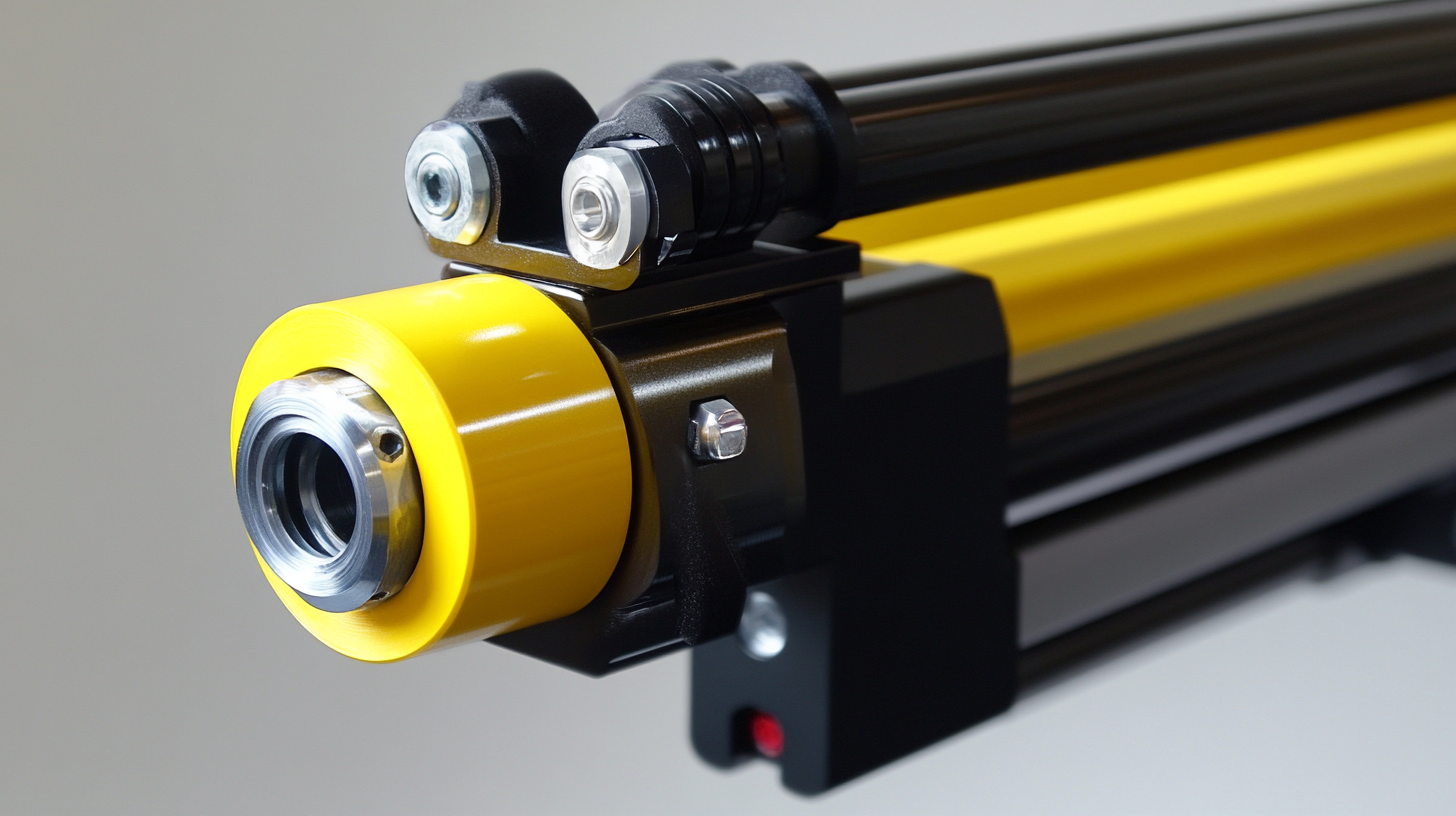

When exploring the excellence of smart hydraulic cylinders, it is essential to focus on the key features that define top-quality products in the market. Among these features, precision engineering stands out, ensuring that the cylinders operate seamlessly under varying loads. Buyers should prioritize products that offer advanced control systems, allowing for enhanced responsiveness and adaptability in diverse applications. These cylinders excel in providing consistent performance, reducing downtime, and increasing overall efficiency.

Additionally, the materials used in construction play a critical role in the durability and longevity of smart hydraulic cylinders. Look for models that incorporate high-strength alloys and corrosion-resistant coatings, which extend the lifecycle of the equipment even in challenging environments. Vibrant performance feedback mechanisms are also important, as they allow users to monitor activity in real-time, ensuring optimal operation. By focusing on these key features, global buyers can make informed decisions and invest in the best smart hydraulic cylinders made in China, suitable for both home and industrial use.

| Feature | Description | Benefits |

|---|---|---|

| Smart Control System | Integrated sensors and IoT connectivity for real-time monitoring and control. | Enhances precision and efficiency, reducing operational costs. |

| Durable Materials | Constructed with high-strength alloys and anti-corrosion coatings. | Increases lifespan and reliability under harsh conditions. |

| Compact Design | Space-saving design suitable for a variety of applications. | Facilitates installation in limited spaces and improves versatility. |

| Energy Efficiency | Utilizes advanced hydraulic technology to minimize energy consumption. | Reduces environmental impact and operational costs. |

| Safety Features | Equipped with overload protection and emergency shut-off systems. | Ensures operator safety and prevents damage to equipment. |

The demand for smart hydraulic solutions has seen a significant surge in 2023, driven by advancements in automation and the growing emphasis on efficiency across various industries. As global markets evolve, manufacturers are increasingly seeking innovative technologies that enhance productivity and reduce operational costs. Smart hydraulic cylinders, equipped with sensors and data analytics capabilities, meet this need by offering real-time monitoring and adaptive performance, thus ensuring optimal operation in dynamic environments.

In China, the development of the best smart hydraulic cylinders has positioned the country as a key player in addressing these global market trends. Chinese manufacturers are investing heavily in research and development to produce high-quality, reliable hydraulic solutions that align with international standards. The focus on smart technology not only boosts the performance of hydraulic systems but also contributes to sustainability by optimizing energy consumption. As global buyers look for advanced solutions, China's role in the smart hydraulic market becomes increasingly pivotal, creating opportunities for partnerships and technological exchange worldwide.

The comparison between smart and traditional hydraulic cylinders reveals significant advancements in performance metrics, especially in industrial applications. Smart hydraulic cylinders leverage digital technology, allowing for precise control of fluid dynamics, which enhances overall efficiency. In contrast, traditional cylinders often lack this level of adaptability, resulting in slower responses and increased energy consumption. For example, the integration of positive flow electro-hydraulic systems in modern machinery has demonstrated dramatic improvements in fuel efficiency—up to 30% less fuel usage—compared to their conventional counterparts.

**Tip:** When selecting a hydraulic system, consider not only the initial cost but also the long-term performance benefits. Investing in smart technology may yield higher returns through reduced operational costs and increased productivity.

Moreover, the shift towards smart hydraulic solutions is driven by the need for sustainability and reduced emissions. Digital hydraulic actuators not only increase the productivity of heavy machinery but also contribute significantly to lowering CO2 outputs. This is crucial as industries move towards more eco-friendly practices.

**Tip:** Regularly monitor and maintain hydraulic systems to ensure optimal performance, as even advanced systems can become inefficient if not properly serviced.

This chart compares the efficiency metrics of Smart Hydraulic Cylinders against Traditional Hydraulic Cylinders in terms of energy consumption, response time, and maintenance frequency.

Investing in smart hydraulic cylinders can significantly enhance operational efficiency and reduce maintenance costs for businesses across various industries. According to a report by MarketsandMarkets, the global hydraulic cylinders market is projected to reach $12.3 billion by 2025, growing at a CAGR of 5.2%. This growth is driven by the increasing demand for automation and advanced technologies in manufacturing processes. Smart hydraulic cylinders, equipped with IoT capabilities, offer real-time monitoring and predictive maintenance, thereby minimizing downtime.

Cost-benefit analysis reveals that while the initial investment in smart hydraulic cylinders may be higher than traditional models, the long-term gains can be substantial. A study from Technavio indicates that incorporating smart technologies can lead to a 20-30% reduction in operational costs and an overall improvement in productivity by up to 25%. This shift not only enhances the lifespan of hydraulic components but also provides data analytics that inform better decision-making and resource allocation. For global buyers seeking competitive edge, investing in China's best smart hydraulic cylinders presents a strategically advantageous opportunity for sustainable growth and innovation.