The landscape of cylinder manufacturing has undergone significant transformation in recent years, driven by advancements in technology and innovative techniques. According to a report by MarketsandMarkets, the global cylinder manufacturing market is projected to reach USD 31.4 billion by 2025, growing at a CAGR of 5.2%. This evolution is characterized by the integration of digital technologies, such as automation and data analytics, which enhance precision and efficiency in production processes.

Moreover, the shift towards sustainable practices is reshaping manufacturing methodologies, enabling companies to produce lighter and more durable cylinders that meet industry regulations while reducing waste. As industries like automotive, aerospace, and construction increasingly rely on high-quality cylinders, understanding these evolving techniques is essential for stakeholders aiming to stay competitive and responsive to market demands.

Moreover, the shift towards sustainable practices is reshaping manufacturing methodologies, enabling companies to produce lighter and more durable cylinders that meet industry regulations while reducing waste. As industries like automotive, aerospace, and construction increasingly rely on high-quality cylinders, understanding these evolving techniques is essential for stakeholders aiming to stay competitive and responsive to market demands.

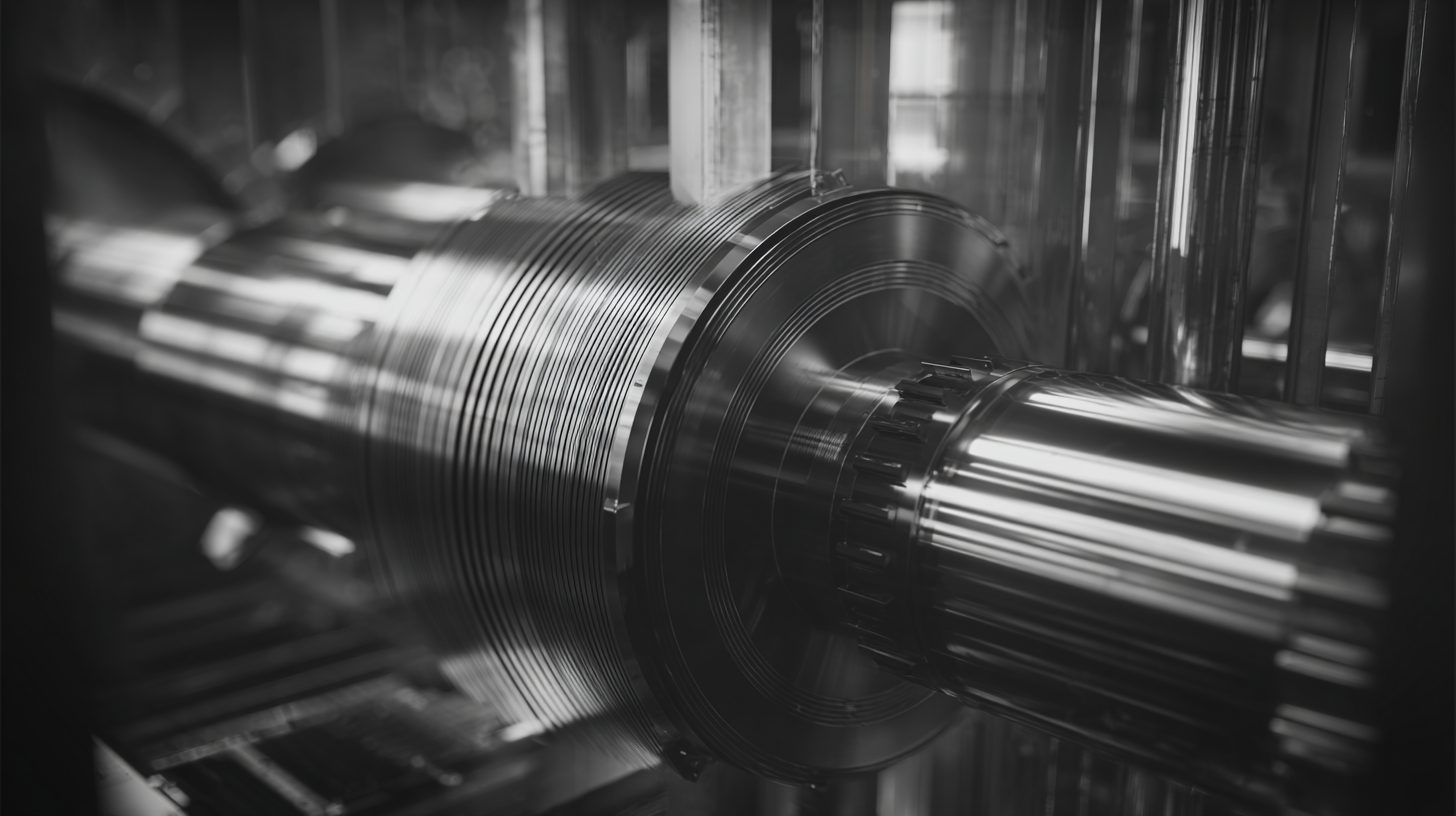

Cylinder manufacturing has undergone significant transformations since its inception, marked by key historical milestones that have shaped modern practices. In the early days, artisans crafted cylinders by hand, relying on primitive tools and techniques that were often inconsistent and labor-intensive. The introduction of the lathe in the 18th century revolutionized the process, allowing for more precise cylinder shaping and the mass production of uniform components. This technological advancement laid the groundwork for the industrialization of cylinder manufacturing.

The 20th century witnessed further innovations with the advent of advanced materials and automated machinery. The development of metal alloys and specialized coatings enhanced the durability and performance of cylinders across various applications. Additionally, computer numerical control (CNC) machining emerged, enabling manufacturers to achieve remarkable precision and repeatability. These milestones not only optimized production efficiency but also opened new avenues for industries such as automotive and aerospace, where the demand for high-performance cylinders continues to grow. As a result, the evolution of cylinder manufacturing techniques has become a cornerstone of modern industrial development.

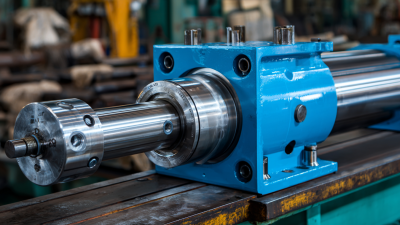

Innovative materials play a crucial role in revolutionizing cylinder production across various industries. Traditional materials such as steel and aluminum have long been the standard due to their strength and durability. However, the rising demand for lightweight, high-performance components has led manufacturers to explore advanced composites and metal alloys. For instance, carbon fiber and polymer composites are increasingly being used in cylinder manufacturing, offering substantial weight reductions while maintaining structural integrity. This shift not only enhances the efficiency of products but also reduces fuel consumption and emissions in applications ranging from automotive engines to aerospace components.

Moreover, the development of additive manufacturing techniques has further transformed the cylinder production landscape. By utilizing techniques such as 3D printing, manufacturers can create complex geometries that were previously impossible to achieve with traditional methods. This technology allows for the production of bespoke designs, optimizing performance and reducing waste through more precise material usage. As industries continue to integrate innovative materials and advanced manufacturing methods, the potential for improved functionality and sustainability in cylinder applications is greater than ever, paving the way for future enhancements in modern engineering and design.

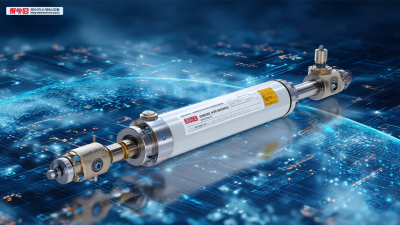

The integration of automation in modern cylinder manufacturing has revolutionized production processes, significantly enhancing efficiency and precision. Automated systems streamline tasks such as material handling, machining, and quality inspection, reducing human error and increasing throughput. With robotics and advanced software, manufacturers can achieve consistent quality in the production of cylinders, ensuring that each item meets stringent industry standards.

Moreover, the adoption of automation allows for real-time data monitoring and analytics, facilitating proactive maintenance and reducing downtime. Predictive algorithms can assess machine performance, enabling manufacturers to anticipate and resolve potential issues before they affect production. This technological shift not only optimizes operational efficiency but also empowers companies to respond swiftly to market demands and customize products with greater flexibility, ultimately driving innovation across various industries.

As manufacturers continue to embrace automation, the future of cylinder production looks promising, characterized by enhanced productivity and reduced costs.

In recent years, the cylinder manufacturing industry has undergone a significant transformation towards sustainability. Traditional manufacturing processes often led to excessive waste and environmental degradation. However, modern practices now emphasize minimizing resource consumption and maximizing efficiency. Manufacturers are increasingly adopting eco-friendly materials and advanced technologies such as additive manufacturing, which allows for precise, on-demand production. This shift not only reduces material waste but also lowers energy consumption during the production process.

Furthermore, many companies are implementing closed-loop systems that recycle materials and integrate waste management strategies. By reclaiming scraps from production lines and repurposing them into new cylinder components, businesses are significantly reducing their ecological footprint. Additionally, the introduction of renewable energy sources in manufacturing plants is becoming more commonplace, allowing for a greener, more sustainable approach to cylinder production. These innovations not only support environmental goals but also enhance the overall economic viability of the industry, paving the way for a more resilient future in cylinder manufacturing.

The cylinder manufacturing industry is witnessing significant transformations, driven by advancements in technology and the evolving demands of modern industries. In particular, the liquefied petroleum gas (LPG) market, projected to be valued at $25.971 billion in 2024, is a prime example of how cylinder manufacturing techniques are adapting to meet market needs. With expectations of growth to $26.8541 billion in 2025 and reaching $35.0893 billion by 2033, this sector is poised for considerable expansion, reflecting a compound annual growth rate of 3.4%.

Future trends in cylinder manufacturing will likely focus on innovations such as automated production processes and smart technology integration. As industries progressively rely on efficient and high-performance cylinders, manufacturers are shifting towards pneumatic elements and intelligent pneumatic technologies. These advances will enhance the reliability and functionality of cylinders in various applications, including the manufacturing and assembly sectors. As the landscape evolves, companies will be challenged to adopt these new techniques to stay competitive in an expanding global market.