Hydraulic cylinders play a crucial role in various industrial applications. Understanding the different hydraulic cylinder types is essential for optimizing performance and efficiency. As noted by industry expert John Smith, “Choosing the right hydraulic cylinder type can significantly enhance system reliability.”

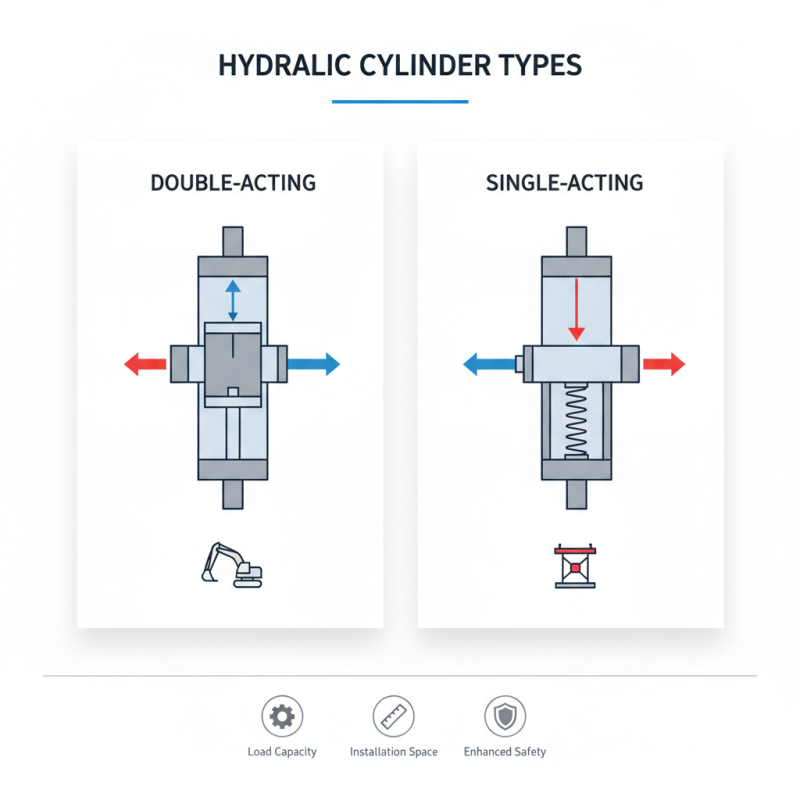

Hydraulic cylinders come in various designs, each suited for specific tasks. For instance, double-acting cylinders generate force in both directions, making them versatile for many applications. On the other hand, single-acting cylinders produce motion in one direction only, often utilizing a spring to return to the starting position. This distinction can impact the overall operation of machinery significantly.

Despite the variety, selecting the appropriate hydraulic cylinder type can be challenging. Not all cylinders are suitable for every application. Sometimes, a deeper understanding of operational requirements is needed. Ignoring factors like load capacity and installation space can lead to inefficiencies. The right choice can result in improved safety and performance, which is a goal worth pursuing.

Hydraulic cylinders are integral in various industries, acting as vital components in machinery. They can be categorized based on design and construction. The most common types include single-acting, double-acting, and telescopic cylinders. Each type serves a unique purpose and is designed for specific applications. According to industry reports, nearly 45% of hydraulic cylinder usage involves double-acting designs due to their efficiency in providing power in both directions.

Single-acting cylinders are simpler. They use hydraulic fluid to extend but rely on gravity or a spring to retract. This design limits their functionality compared to double-acting cylinders. The latter utilizes hydraulic pressure for both extension and retraction. This makes double-acting cylinders more versatile and popular in industries like construction and automotive. However, they can be more complex and may require regular maintenance, which can be a drawback for some operators.

Telescopic cylinders are another design variant. These cylinders consist of multiple nested sections. They offer long strokes in a compact size. Often found in dump trucks, they’re crucial for space-saving applications. However, their intricate construction can pose challenges in repair and upkeep. As each type comes with its strengths, choosing the right design requires thoughtful consideration of the application and operational demands.

| Type | Design | Construction | Applications |

|---|---|---|---|

| Single-Acting Cylinder | Piston and cylinder | Open bottom | Lifting and pushing |

| Double-Acting Cylinder | Piston with hydraulic fluid on both sides | Sealed ends | Actuation in both directions |

| Telescopic Cylinder | Multiple nested cylinders | Compact design | Dump trucks, excavators |

| Rotary Actuator | Rotating motion | Specialized design | Machine tooling, robotics |

| Plunger Cylinder | Plunger in a sleeve | Robust structure | Metal forming, presses |

Hydraulic cylinders are essential components in many industrial applications. They can be categorized into different types, with single-acting and double-acting cylinders being the most common. Understanding the differences between these two types can greatly enhance operational efficiency.

Single-acting hydraulic cylinders use fluid pressure to move in one direction. The return movement usually relies on a spring or gravity. This design is simpler and lighter. However, the limitation is notable. They are not ideal for tasks requiring precise control in both directions. For example, lifting equipment may work well but struggles to lower it accurately.

On the other hand, double-acting hydraulic cylinders function differently. They utilize hydraulic pressure for both extending and retracting. This capability allows for more control and power during operation. The complexity increases, requiring more components and maintenance. Users might find these cylinders more costly upfront. Yet, for tasks needing reliable performance in both directions, double-acting systems prove their worth. Understanding these aspects can help users make informed decisions based on their specific needs.

Telescopic hydraulic cylinders are essential in many industrial applications. They consist of multiple nested cylinders. This design allows them to extend significantly while occupying minimal space. Their compact size makes them ideal for tight areas where regular cylinders might not fit.

These cylinders are commonly used in mobile equipment, such as cranes and excavators. They provide the necessary lifting power without requiring much space. When fully extended, they deliver impressive force and reach. Yet, when retracted, they save valuable space on transport vehicles.

Tip: Regular maintenance is crucial for the longevity of telescopic cylinders. Check for leaks and ensure proper lubrication.

One challenge with telescopic cylinders is their complexity. They have multiple seals and joints, which can wear out over time. Ensuring that these components are in good condition requires attention. Ignoring small issues can lead to bigger problems later. Proper installation is equally important to avoid operational failures.

Tip: Always review the manufacturer's specifications. This ensures compatibility and performance.

In practical terms, telescopic cylinders may not always function flawlessly. Some users report issues with extended reach. It's essential to consider the load's weight and distribution. Misestimating these factors can lead to accidents. Always assess load stability for safe operation.

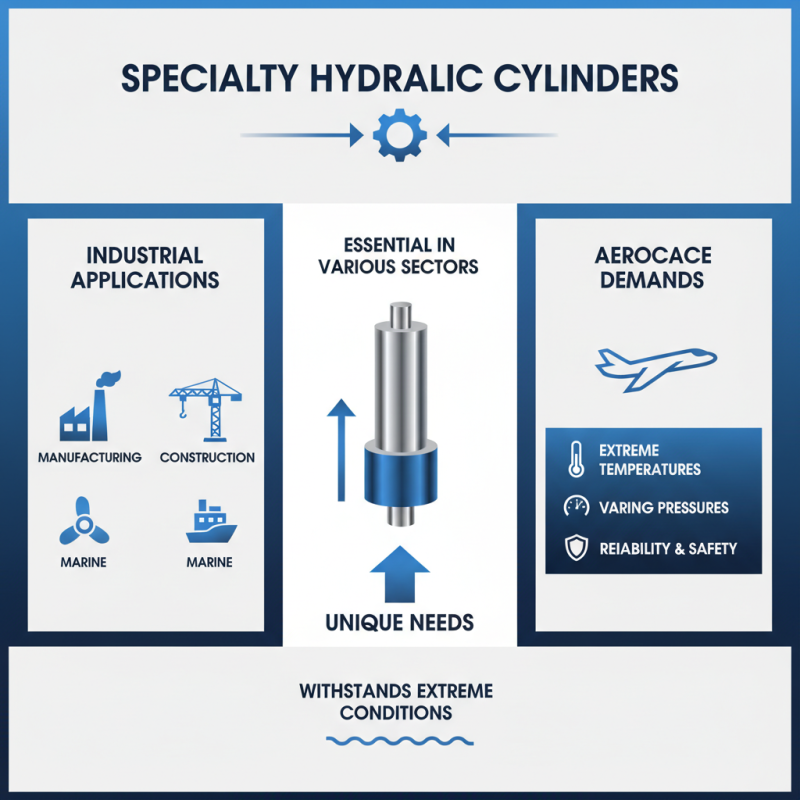

Hydraulic systems are essential in various industrial applications. Specialty hydraulic cylinders serve unique needs across many sectors. For instance, those used in aerospace must withstand extreme conditions. These cylinders can function under varying temperatures and pressures, ensuring reliability and safety.

Data from the Hydraulic Components Market Analysis suggests that specialty cylinders are seeing a growth rate of around 5.4% annually. Many industries, such as construction and marine, require specialized designs to meet their operational demands. Customization in size, stroke length, and mounting options is critical. However, variations in manufacturing can lead to inconsistent quality.

Additionally, some applications face challenges with durability. Specialty cylinders must often endure harsh environments, which can lead to premature failure. Regular inspections and maintenance become vital. Mitigating risks tied to these cylinders is crucial for optimal performance. Despite advancements, companies sometimes struggle with integrating new technologies. The diverse needs of industries call for ongoing innovation and adaptation. As the market evolves, the focus must remain on improving efficiency and reliability.

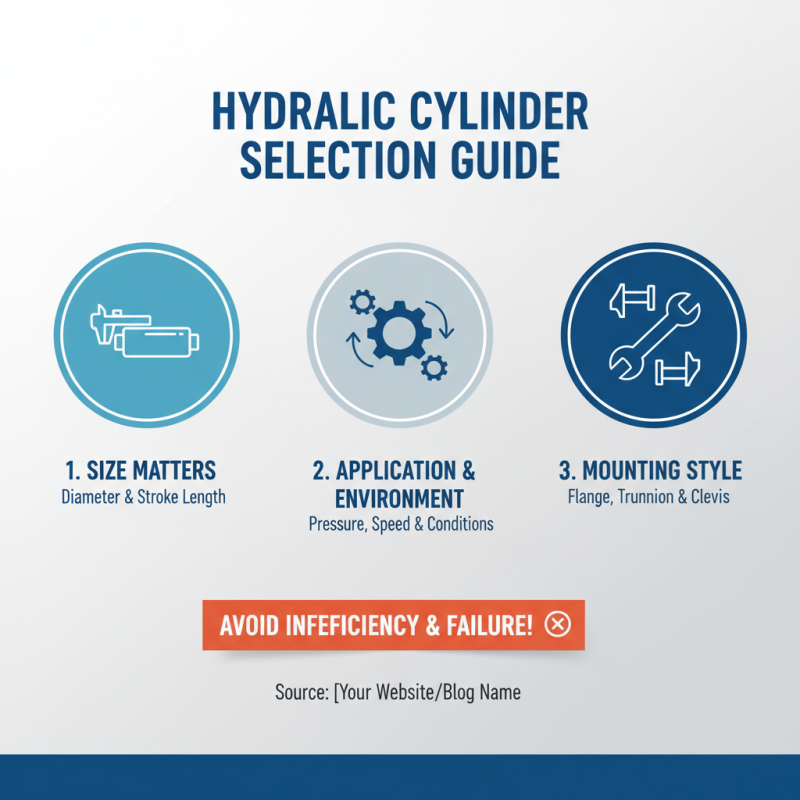

Selecting the right hydraulic cylinder for your project can be daunting. Different applications and environments require specific features. It's vital to know what diameter, stroke length, and mounting style you need. A wrong choice might lead to inefficiency or even project failure.

Consider the operational pressure and speed as well. Some jobs need high-speed action, while others require stable, slow movements. Think about the materials as well. For example, a rust-resistant cylinder might be necessary for harsh conditions. Dimensions largely depend on the space available and the load capacity.

Don’t forget maintenance requirements, too. Some cylinders need regular checks, while others might last longer with minimal service. Inadequate planning can lead to unforeseen issues. Reflect on your priorities before making a decision. Ensure every detail aligns with your project goals.