In the field of metallurgy, the importance of precision cannot be overstated. An Alloy Powder Grader emerges as a crucial tool in this landscape. It expertly categorizes alloy powders based on size and quality. This process is vital for ensuring consistency in manufacturing and enhancing final product performance.

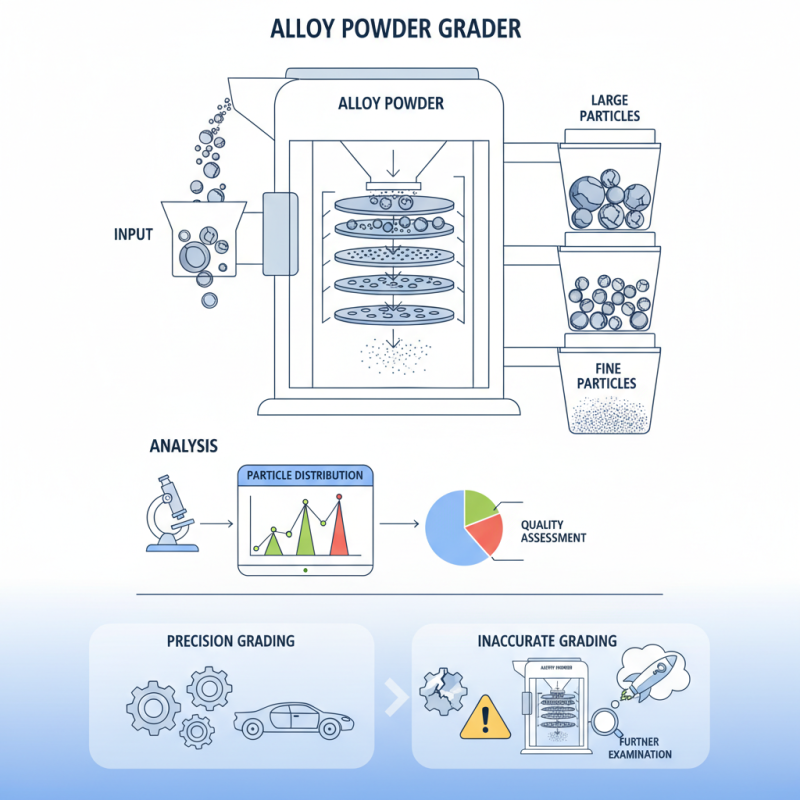

The Alloy Powder Grader operates through a combination of sieving and analysis. It uses advanced technology to assess particle distribution. However, challenges remain. Sometimes, the grading is not as accurate as desired. This potential for error can lead to significant impacts on production.

Exploring the role of an Alloy Powder Grader reveals its significant effects on industries like aerospace and automotive. Quality control is paramount. Inaccurate grading may undermine safety and efficiency, prompting further examination of procedures. Understanding this tool’s limitations can lead to improvements in metallurgical practices.

An alloy powder grader is a critical tool in the metal processing industry. It is designed to classify powders based on particle size and distribution. This process is essential for applications in additive manufacturing, where precise material properties are crucial. According to recent industry reports, over 60% of metal powder applications require specific size distributions to ensure optimal performance.

These graders function by utilizing various techniques, including sieve analysis and laser diffraction. Sieve analysis helps in separating powders into distinct size categories. Meanwhile, laser diffraction provides data on particle size distribution in a continuous flow. This dual approach enhances accuracy, but some challenges remain. For instance, the calibration of grading equipment can sometimes lead to inconsistent results.

In practice, incorrect grading can affect the mechanical properties of the final product. This can lead to issues like reduced durability or unexpected porosity in metals. Industry studies indicate that a mere 10% variation in powder size can significantly impact the sintering process in manufacturing. Thus, maintaining strict control of the grading process is paramount. The technology is evolving, yet there is still room for improvement in precision and reliability.

An alloy powder grader is essential in the manufacturing process of metal powders. It ensures that the particle sizes are uniform, impacting the overall quality of the final product. Key components within this grading system include screens, vibratory motors, and collection chambers. Each part plays a crucial role in the ability to sort and refine alloy powders effectively.

Screens are universally used in grading systems. They separate particles based on size. Different mesh sizes cater to specific applications. Vibratory motors enhance the movement of powders across these screens. The motion created allows finer particles to pass through while retaining larger ones. Reports indicate that using precise vibration control can improve grading accuracy by up to 25%.

The collection chamber is another vital aspect. It captures the graded powders for further processing or packaging. An efficient collection system can minimize waste and contamination. Studies reveal that effective use of these grading components can boost productivity significantly. However, the system's complexity can lead to operational challenges. Regular maintenance checks are crucial but often overlooked. This oversight may lead to inconsistent grading results. Reflection on these operational flaws can inspire improvements in design and functionality.

Alloy powder graders are essential in material processing. They ensure the proper mixture of powders for various applications. Understanding how they function is key to maximizing their efficiency.

The step-by-step process begins with loading. Powders are carefully measured and placed in the grading machine. Next, the machine uses vibrations or air flow to segregate particles based on size. This separation process is crucial. Consistency matters in the final product.

Tips: Regularly check calibration to ensure accuracy. Inconsistent readings may lead to faulty mixtures. Observe particle uniformity before using the graded powders. It affects the end-product quality significantly.

After grading, validation takes place. Samples are tested to ensure they meet specifications. This step cannot be skipped. Mistakes here can lead to serious issues. Make sure to document findings meticulously. A paper trail protects against future errors.

Alloy powder grading plays a crucial role in various industries. This process involves sorting alloys based on particle size and composition. Accurate grading ensures the quality and performance of finished products.

In manufacturing, alloy powders are used in 3D printing and metal injection molding. These techniques require precise control over the powder characteristics. Inconsistent grading can lead to defects in the final items. For instance, improper particle size can cause issues during the melting process, affecting strength and durability.

The automotive sector also benefits from alloy powder grading. Components made from fine powders offer superior performance. However, if the grading is not managed well, it can create problems. Some manufacturers struggle with achieving the desired properties consistently. This highlights the need for meticulous grading techniques in production lines.

An alloy powder grader is a vital tool in manufacturing. It helps ensure consistent quality in metal production. These graders sort alloy powders based on their particle size. The precision of this grading affects the final product. Variability in particle size can lead to defects.

Using an alloy powder grader offers several advantages. It enhances product uniformity. This means fewer defects in the final output. Inconsistent powder can cause issues in processes like sintering. Manufacturers can avoid costly mistakes by grading powders accurately.

Moreover, efficient grading can optimize production speed. Workers spend less time on quality checks. However, not all graders are created equal. Some may struggle with very fine powders. This can lead to frustration. Finding the right machine requires careful consideration. It’s an ongoing challenge in the industry.