In the fast-evolving manufacturing sector, the Slitter Cutter Machine stands out as a vital tool. Industry expert John Doe once stated, "Innovation in slitting technology shapes the future of production." This highlights the importance of understanding its features and benefits.

The 2026 models promise cutting-edge advancements. These machines boast improved precision and efficiency. Enhancements in blade design and automation can save time and reduce waste. However, users must consider operational challenges and maintenance needs.

While the benefits are clear, the learning curve might be steep for some. Adapting to new technology requires training and adjustment. How businesses embrace these changes will affect their competitiveness. Understanding the Slitter Cutter Machine remains crucial for success in the industry.

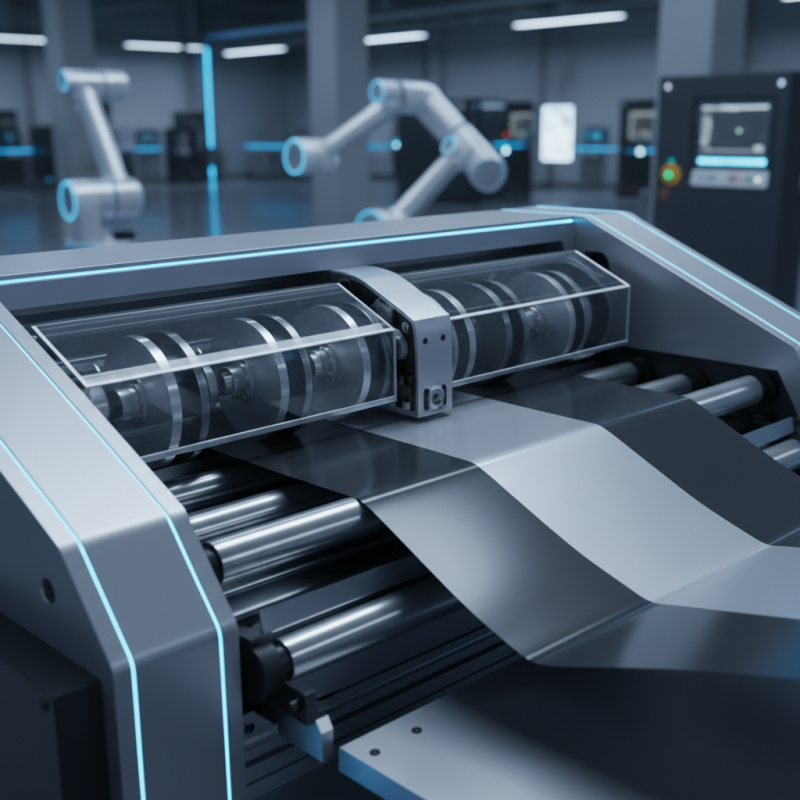

Slitter cutter machines have evolved significantly by 2026. These machines are crucial in various industries, primarily for cutting materials into narrow strips. Their efficiency has improved, offering faster and more precise cutting options. With advanced technologies, slitter cutters can now handle a variety of materials, from paper to plastic. This versatility optimizes production processes.

One standout feature in 2026 is the enhanced user interface. Operators can easily set parameters and monitor performance in real time. While this makes operation smoother, it also requires training. Not all operators adapt quickly to new technology. Some may find the transition challenging, raising concerns about productivity in the initial phase.

Another critical benefit is the reduction in waste. Modern machines are designed to minimize material loss during the cutting process. However, inconsistencies in materials can still lead to unexpected waste. This aspect often necessitates careful quality control. Users might overlook it initially, but addressing it can greatly enhance overall efficiency. The advancements in 2026 offer numerous benefits, yet they come with their obstacles.

Advanced slitter cutter machines play a crucial role in various industries. They enhance operational efficiency while ensuring precision and quality in material processing. The key features of these machines include high-speed cutting capabilities, customizable blade designs, and user-friendly interfaces. According to industry reports, over 75% of manufacturers prioritize these attributes when selecting equipment.

Efficiency is paramount. Modern slitter cutters often operate at speeds exceeding 500 meters per minute. This can significantly reduce production time. Additionally, customizable blade configurations allow for versatility in processing different materials, from paper to metals. The ability to adjust settings easily enhances productivity. However, operators must be trained adequately. Misuse can lead to reduced effectiveness and increased waste.

Tips: Always conduct regular maintenance checks to prolong machine life. A well-maintained cutter operates smoother and cuts cleaner. Monitor blade wear closely. Dull blades can compromise quality and increase costs. Pay attention to safety protocols as well. Ensuring a safe work environment cannot be overlooked. Regular training sessions for operators can help prevent accidents and improve operational efficiency.

Modern slitter cutter technologies offer numerous benefits that enhance efficiency and precision in various industries. One significant advantage is the ability to produce uniform cuts. This precision reduces material waste and ensures consistent quality, which is vital for customer satisfaction. Less scrap means more savings and better sustainability over time.

Investing in advanced slitter cutter machines can boost productivity. These machines handle materials with diverse thicknesses and widths. They adapt quickly to different materials, saving time and labor costs. Imagine the efficiency gained when switching between tasks with ease!

**Tip:** Regular maintenance is crucial. A well-maintained slitter cutter performs better and lasts longer. Neglect can lead to breakdowns, causing costly delays.

Another noteworthy feature is automation. Modern machines come equipped with smart technology, allowing for real-time monitoring. This can lead to quicker adjustments during the cutting process. However, reliance on technology can sometimes lead to oversights. Operators must stay alert and involved in the process.

**Tip:** Investing in training is key. Properly trained operators maximize the potential of the machinery and minimize errors.

Slitter cutter machines play a vital role in various industries today. Their applications range from paper converting to flexible packaging and textiles. Recent industry reports highlight that demand for these machines is expected to grow by 5.3% annually until 2028. This growth stems from the rising need for precision in material cutting and processing.

In the paper industry, slitter cutters can achieve high-speed operations. They allow for various widths and lengths, enhancing productivity. According to a study, nearly 70% of manufacturers prefer automated slitting processes for efficiency and accuracy. Additionally, in the packaging sector, these machines are instrumental in producing films and foils. Their adaptability to different materials makes them indispensable.

However, not all slitter cutters perform optimally in every environment. Some machines may struggle with certain materials, leading to waste. Companies need to understand their specific requirements. Choosing the right machine is crucial for minimizing errors and improving output quality. Awareness of operational limitations can help businesses make informed decisions.

The future of slitter cutter machines is evolving rapidly. With advancements in technology, machines are becoming more efficient. Automation is a key trend. It reduces human error and increases precision. Operators can rely on smarter systems to monitor performance in real-time. This can minimize downtime significantly.

Sustainability is becoming important too. Many manufacturers are focusing on eco-friendly materials and energy-efficient designs. This shift helps reduce waste and lower operational costs. Users may face a learning curve when adapting to these new technologies. However, the long-term benefits, like reduced energy consumption, are worth considering.

Customization options are also on the rise. More machines will allow users to adjust settings easily. Different materials may require unique slitting configurations. Flexibility in machine design could help meet diverse industry needs. Yet, with more features comes complexity. Operators might struggle initially with these advancements. Balancing innovation with usability will be essential for success.