As we advance towards 2025, the integration of technology in industrial applications is rapidly transforming the landscape of machinery and automation. Among these innovations, the Smart Hydraulic Cylinder stands out as a pivotal element that enhances efficiency, precision, and safety in various industrial settings. This blog will delve into the future insights surrounding Smart Hydraulic Cylinders, exploring their benefits, applications, and the technological advancements driving their evolution. We will provide valuable tips on selecting the best Smart Hydraulic Cylinder for specific industrial needs, as well as discuss the anticipated market trends that will shape their adoption in the coming years. Join us as we uncover the critical role that Smart Hydraulic Cylinders will play in optimizing manufacturing processes and improving operational effectiveness in a digitized industrial environment.

The increasing adoption of smart hydraulic cylinders in industrial applications signifies a transformative shift within the hydraulic equipment sector. According to a recent analysis, the global industrial hydraulic equipment market is projected to reach a value of USD 52.6 billion by 2033, with a compound annual growth rate (CAGR) of 5.7% from 2025 to 2033. This growth is largely attributed to advancements in technology, which have facilitated the development of smart hydraulic solutions that enhance efficiency, reliability, and overall performance of machinery.

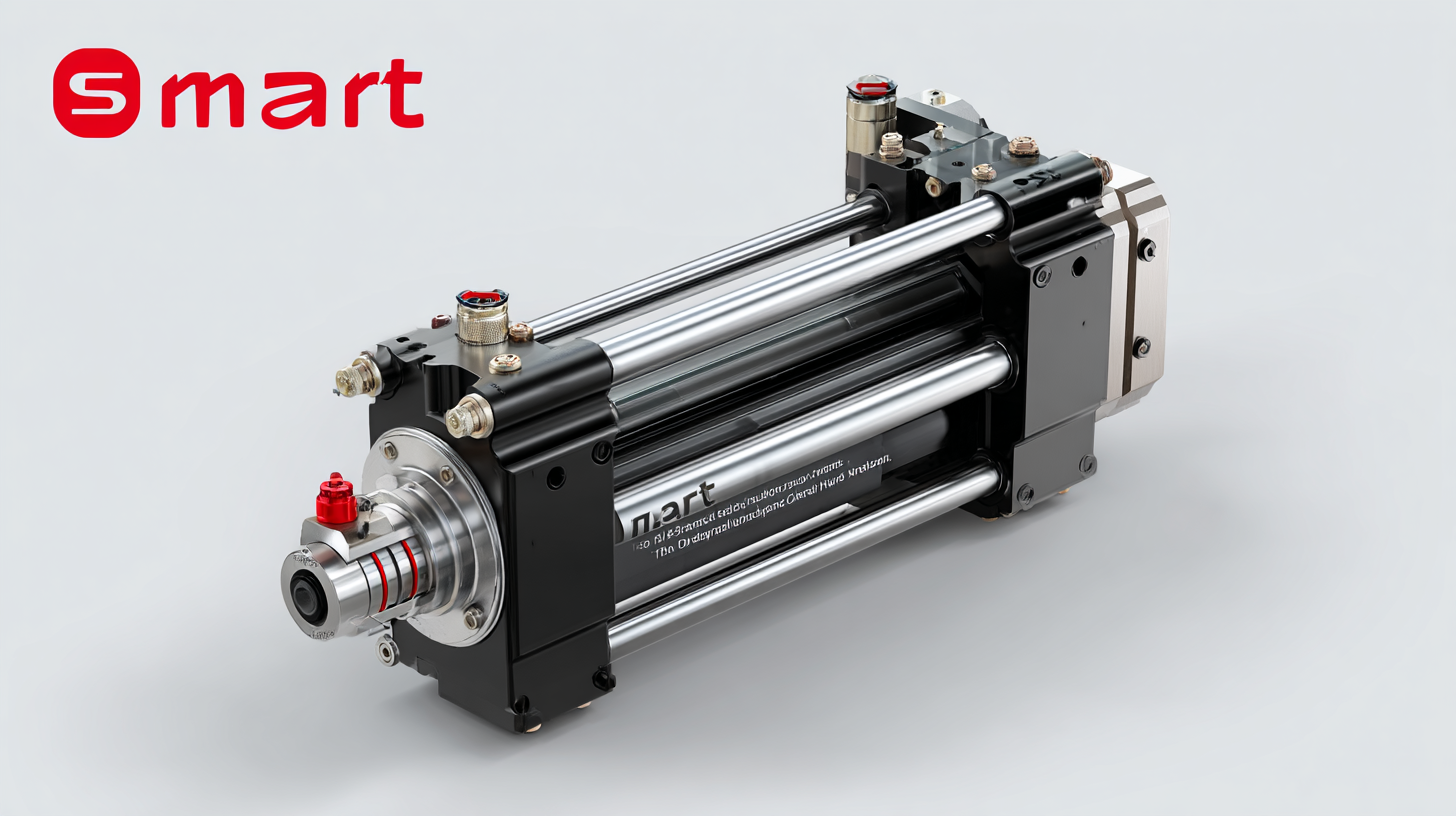

Smart hydraulic cylinders are becoming essential components in various industries, driving automation and improving operational precision. These cylinders utilize real-time data and smart sensors to optimize performance, allowing for predictive maintenance and reducing downtime. The Hydraulic Cylinder Market is expected to see significant expansion as industries increasingly prioritize intelligent solutions. Reports indicate that by 2035, the demand for these advanced hydraulic systems will continue to rise, underscoring their critical role in the evolution of manufacturing processes and heavy machinery applications. As companies look to streamline operations and maximize productivity, the growing importance of smart hydraulic cylinders will remain a key focus in future industrial strategies.

This chart illustrates the projected growth of the smart hydraulic cylinder market from 2023 to 2025, highlighting key application areas in various industries.

As industries continue to evolve, the integration of smart hydraulic cylinders is becoming a pivotal factor in enhancing operational efficiency and productivity. The 2025 market insights reveal that the adoption of intelligent hydraulic systems can increase machinery performance by up to 30%, thanks to real-time monitoring and adaptive control features. These advancements facilitate predictive maintenance, enabling businesses to reduce downtime and minimize maintenance costs significantly.

Key features of smart hydraulic cylinders, such as IoT connectivity and advanced sensor technology, play a crucial role in optimizing performance. According to a report by MarketsandMarkets, the global smart hydraulic systems market is projected to grow from $13.2 billion in 2020 to $21.8 billion by 2025, representing a compound annual growth rate (CAGR) of 10.4%. This growth underscores the vital role that these innovative solutions play in automating industrial processes, ultimately leading to enhanced productivity and operational efficiency across various sectors. Additionally, smart cylinders provide precise control and greater safety margins, further solidifying their place in modern industrial applications.

In the rapidly evolving industrial sector, the integration of smart technology into hydraulic systems is set to revolutionize operational efficiency and cost-effectiveness. The anticipated growth in the smart hydraulic cylinders market highlights the potential for substantial long-term savings. As industries shift towards automation, the market for smart hydraulic solutions is projected to witness remarkable expansion. A recent analysis indicates that smart technology can reduce operational costs by 15-30% through improved energy efficiency and minimized downtime, making it an attractive investment for businesses aiming to enhance productivity.

Simultaneously, the boiler market, segmented by commercial and residential applications, is also on an upward trajectory. Driven by the increasing demand for sustainable solutions, the market is expected to grow significantly from $3 billion in 2022 to nearly $5 billion by 2030. Moreover, the server power supply market, valued at $570 million in 2022, is anticipated to reach $1.05 billion by 2030, reflecting a CAGR of 8.2% from 2024 to 2030. Such trends underscore the pivotal role that smart technology plays across various industries, driving both innovation and cost reduction while aligning with broader sustainability goals.

The future of smart hydraulic cylinders is poised to transform several key industrial sectors, from manufacturing to logistics. In manufacturing, these advanced cylinders enable greater precision and efficiency in automation processes. With the ability to monitor performance in real-time, manufacturers can make data-driven decisions to optimize their workflows and reduce downtime. Smart hydraulic cylinders are particularly beneficial in assembly lines, where speed and accuracy are paramount.

In logistics, the integration of smart hydraulic cylinders enhances the functionality of forklifts and automated guided vehicles (AGVs). By providing real-time feedback and adjusting to load conditions automatically, these cylinders can significantly improve material handling efficiency. This not only streamlines operations but also reduces the risk of accidents, thereby ensuring a safer work environment.

Tips for implementing smart hydraulic cylinders include assessing your current systems for compatibility and investing in training for staff on the new technology. Furthermore, maintain clear communication with suppliers to ensure you receive updates on software and hardware developments, which can help you get the most out of your investment. Prioritizing maintenance schedules can also help prolong the life and efficiency of your equipment.

As the industrial sector continues to evolve, one of the key innovations shaping the future of smart hydraulic cylinders is the integration of advanced IoT technologies. According to a report by MarketsandMarkets, the global market for IoT in industrial applications is projected to reach USD 110.6 billion by 2025, growing at a CAGR of 26.9% from 2020. This rapid growth emphasizes the increasing reliance on interconnected systems, which enhance operational efficiency and predictive maintenance by providing real-time data analytics.

Moreover, the development of smart hydraulic cylinders is also being influenced by advancements in artificial intelligence and machine learning. In a recent study by Mordor Intelligence, it was noted that the adoption of AI in industrial automation can help reduce equipment downtime by up to 20%. These technologies enable hydraulic cylinders to adapt to varying loads and operational conditions, optimizing performance and reducing energy consumption. As manufacturers incorporate these innovations, the future of smart hydraulic cylinders looks promising, delivering not only improved performance but also sustainability in industrial applications.